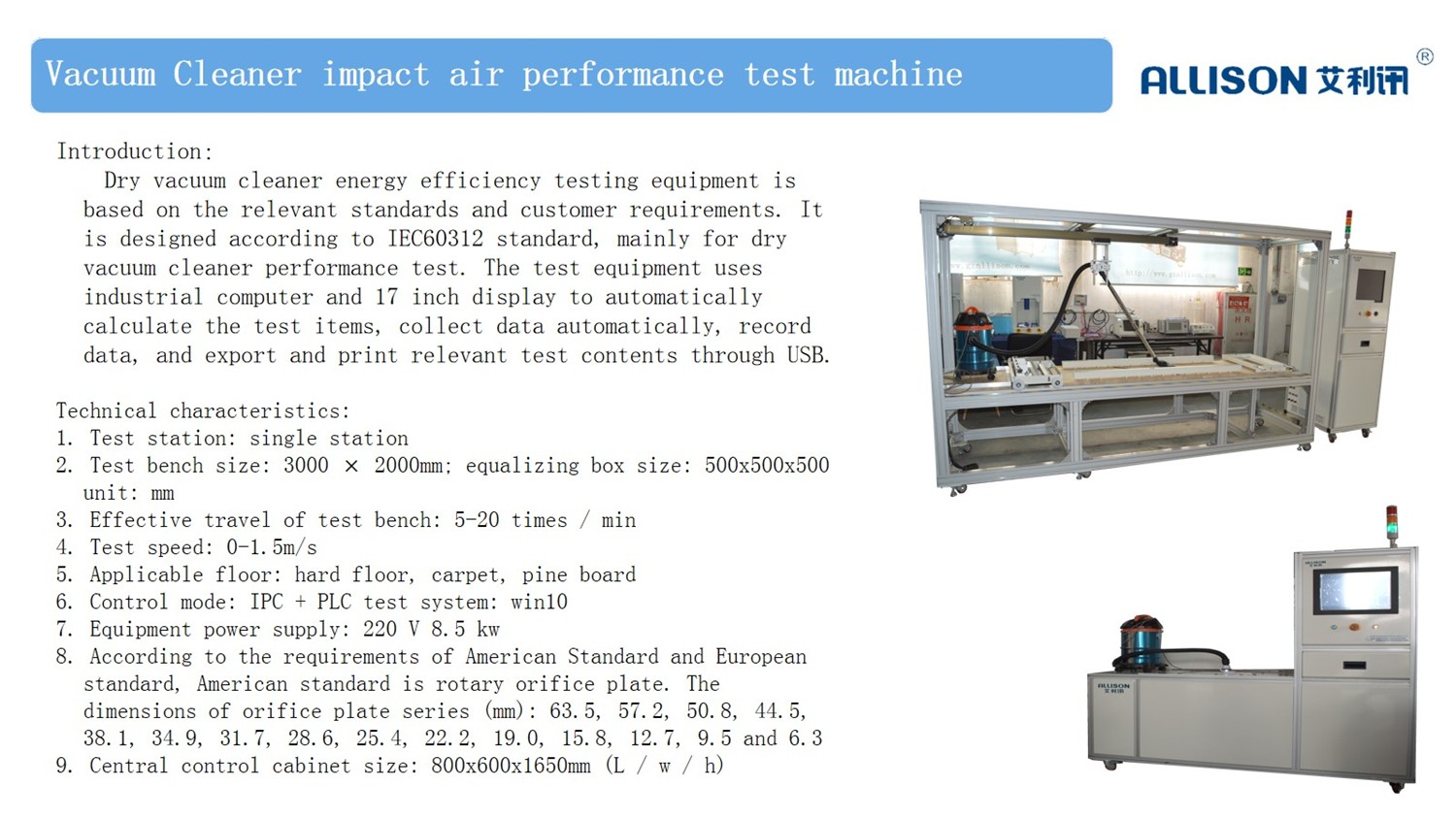

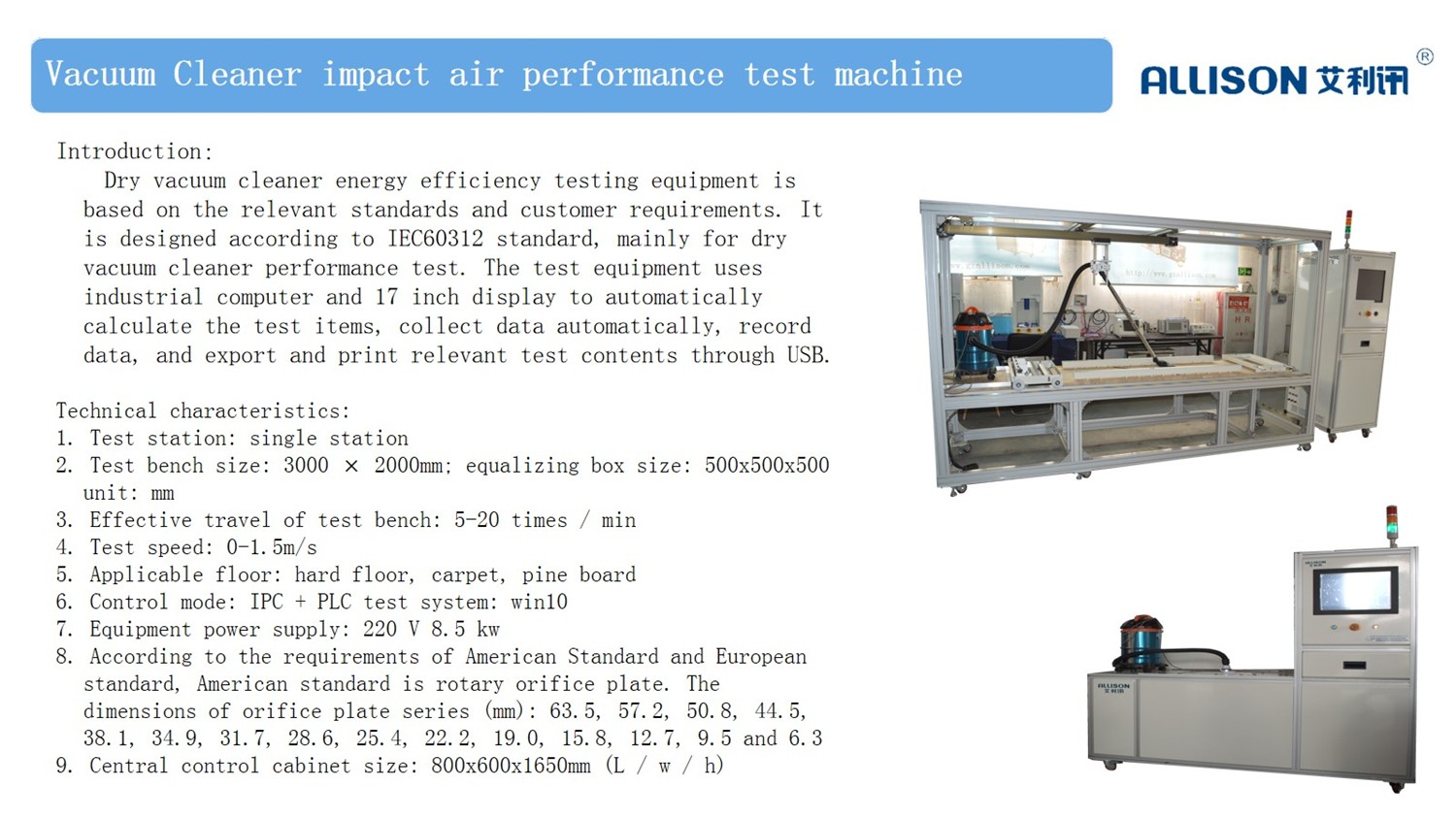

The vacuum cleaner performance test bench is manufactured according to GB/T20291.1-2014 IEC60312-2010, EN62885-2010, and related standards,

and is commonly used for 9% of the vacuum cleaner products on the market (handheld, bucket, household, commercial, etc.).

The equipment meets the relevant test requirements for the dust removal efficiency and removal capacity test of vacuum cleaners.

At the same time, it meets the test requirements for the dust removal capacity of standard wooden floors/test carpets and the dust removal capacity test crevices.

Through the servo linear mechanism, the tested vacuum cleaner is driven to perform reciprocating motion, simulating the operation of manual vacuum cleaners.

Through PLC control the entire test action process is completed. The test equipment uses our company's independently developed control system,

and the relevant formula and measurement report are automatically calculated and output through PLC

The vacuum cleaner dust removal performance test bench is mainly used for the test and evaluation of the dust removal efficiency

and dust removal capacity of vacuum cleaners. The equipment is controlled PLC, and the PLC controls the servo mechanism to drive the vacuum cleaner

to simulate the actual working conditions and evaluate the dust removal capacity of the vacuum cleaner. At the time, the equipment has the functions of automatic dust spreading,

roller pressing, and motion resistance test. Through PLC related settings and control, the tested vacuum cleaner simulates the actual conditions at a adjustable speed of 0-1.0M/s, such as floor, carpet, groove, etc. test platforms for back and forth motion.

During the, the system collects related voltage, current, power, electricity and other parameters,

and records related test data. Related test data can be exported through USB and can be printed.

The platform is widely used for the dust removal capacity performance test of vacuum cleaners

by various vacuum cleaner manufacturers and testing institutions.

Main accessories:

Test carpet 1 piece,er car 1 piece, T-shaped right-angle device, distribution template 2 pieces, test test floor, test frame,

carpet hanging automatic lifting hanger 3 workations, dust beating machine 1 piece (manual), carpet clamping device 2 pieces,

groove test plate, electronic scale, fabric adjustment frame, etc

Online

Online Tel

Tel Contact

Contact Home

Home