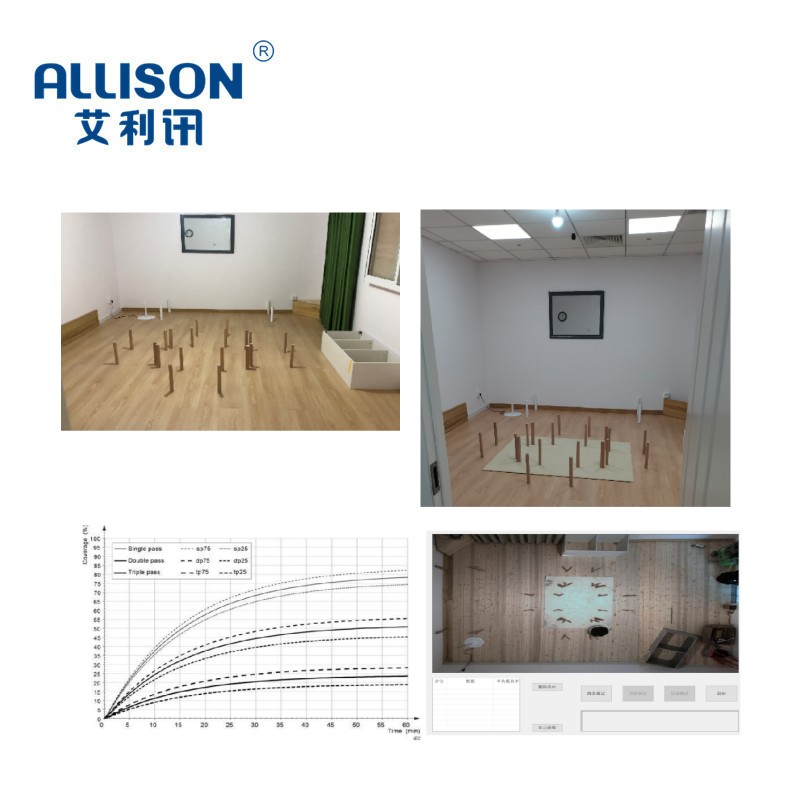

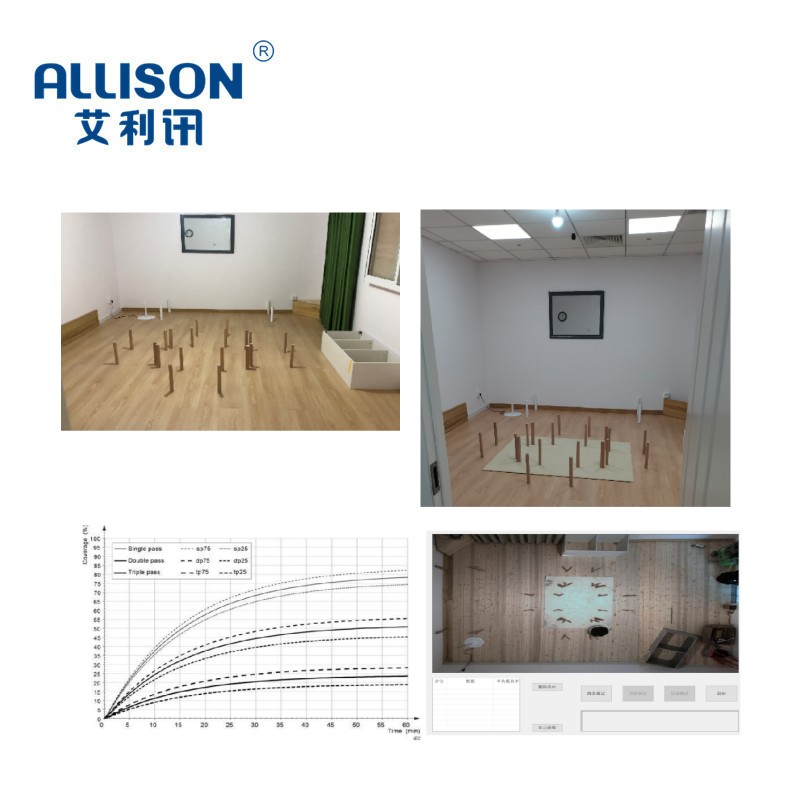

Overview 1. The IEC testing room is developed based on the coverage testing room standards in section 7.1 of the performance testing

methods for dry cleaning robots in relevant standards GB/T34454-2017, IEC62885-7, T/CAS 378, and IEC62929:2014. 2. It is mainly used

to test the dust removal ability of the testing vacuum robot in a designated standard room within a specified time, covering the reachable

area. By testing the internal layout of the room, a large wide-angle high-definition visual camera and a self-developed visual tracking object

motion trajectory system are installed on the top to monitor the real-time position coordinates of moving objects. The coordinate address is

transmitted to the upper computer system, and the coordinate data collected by the camera is further processed with algorithms and embedded

deep learning, combined with high-definition visual cameras. Finally restore the actual motion trajectory of the moving object and simulate and display the

trajectory. The relevant test data can be exported through USB

Main components:

1. The trial area is mainly composed of assembled buildings with dimensions of 4 meters X 5 meters X 2.5 meters high inside the building (see attached figure).

The building is constructed according to the customer's on-site drawings (as shown in the figure below). The testing floor of the room is composed of pine boards

spliced together. The top of the room is decorated with a square shaped ceiling. Room measurement section: overall dimensions of the room, (length X width X height)

internal lighting illumination and color temperature of the room. Internally simulate the distribution of furniture, including food cabinets, tables, chairs, sofas, partitioned

cabinets, floor lamps, power cords, obstacles, heater substrates, carpets, grids, pressure strips, and other simulated items in the actual testing site.

Online

Online Tel

Tel Contact

Contact Home

Home