According to the relevant standards for pressure resistance and pressure impact of automotive parts, the equipment meets the requirements for pressure pulse testing and pressure burst testing under high and low temperature environmental testing. High-frequency pressure pulse testing and burst testing are conducted on the tested products at an ambient temperature ranging from -40 to 150 degrees and a water pressure of 1-10 MPa. Comprehensive performance evaluation is performed on the tested products.

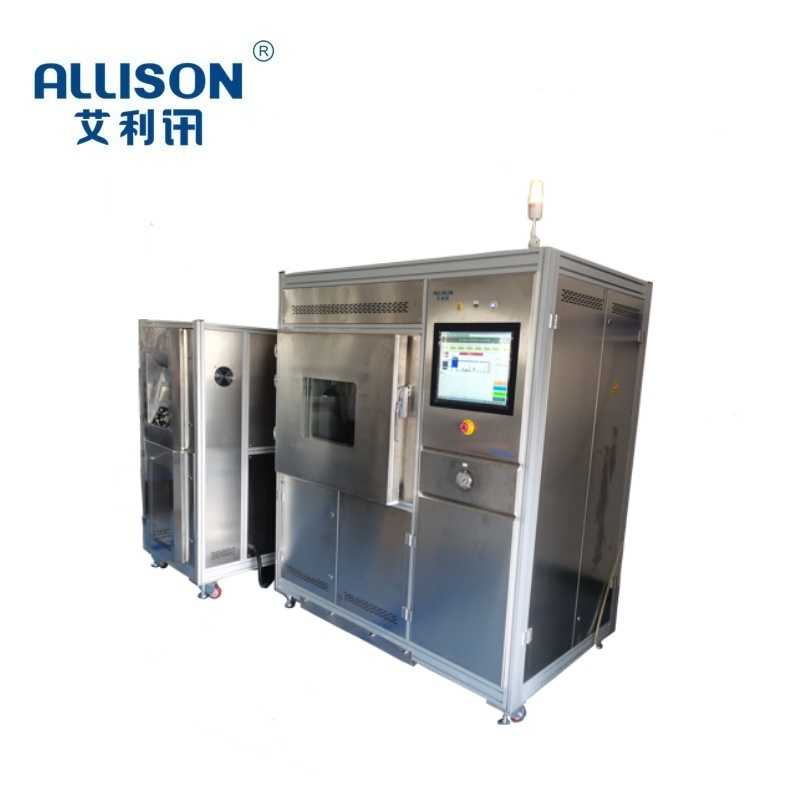

The pulse burst life tester is controlled by a Japanese Mitsubishi PLC and displays on a 17-inch monitor. Relevant tests are completed through the setting and control of relevant parameters. Relevant test data can be exported and printed via USB.

3. The testing machine adopts ergonomic design, featuring an up-flipping explosion-proof door. It is equipped with LED lights and an automatic shutdown function when the door is opened. The testing door adopts a grid-style explosion-proof design, and the working platform is made of 304 stainless steel water tray. It can effectively prevent rust and facilitate the recovery of test liquids. The equipment operates using a self-developed system, which is easy to operate and does not require specialized personnel.

4. The box body is constructed with external powder coating and internally assembled using 304 stainless steel. It features alarms for overtemperature, overpressure, and water leakage, as well as automatic shutdown functionality.

Online

Online Tel

Tel Contact

Contact Home

Home