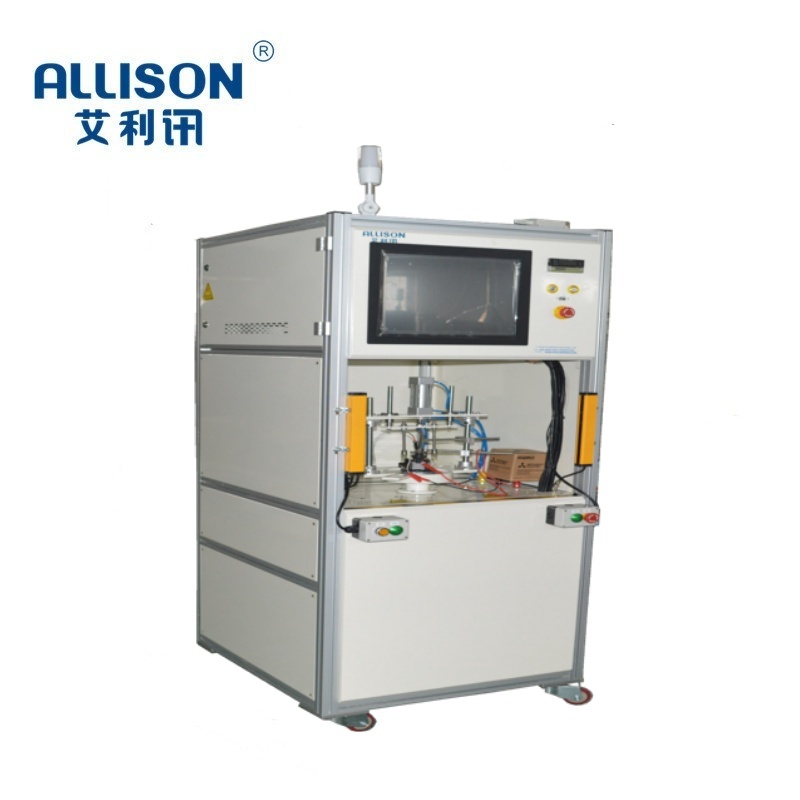

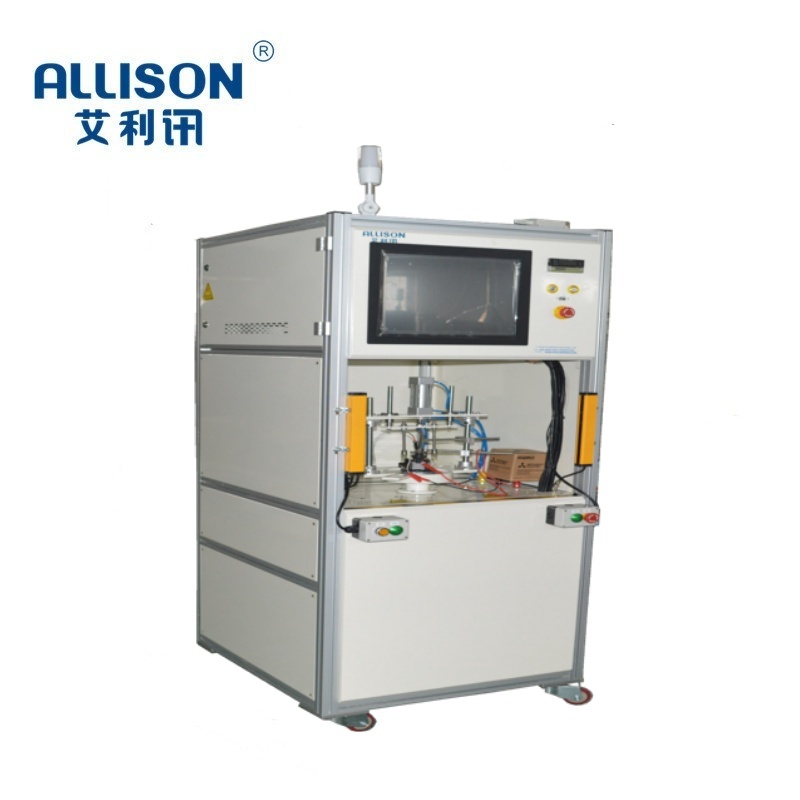

The air performance (production line) testing equipment for vacuum cleaner motors is mainly manufactured according to relevant testing standards such as GB/T20291-2014, IEC60335-2, IEC60312, etc. The air performance testing equipment is mainly used for comprehensive performance testing of the motor in vacuum cleaners. The testing parameters include motor motor, voltage detection, current detection, input power detection, power factor, suction power, speed, flow rate, vacuum degree, and efficiency. Through PLC control and monitoring, the actual simulated motor is tested under three operating conditions: fully open/fully blocked/13MM semi blocked, along with relevant air performance data. And determine the qualification and non qualification before leaving the factory through relevant parameters such as vacuum degree, flow rate, voltage, and current. Widely applicable to various vacuum cleaner manufacturers and testing institutions for comprehensive performance testing of vacuum cleaner motors.

1. Control the valve fully open, fully blocked, and partially blocked (13MM orifice plate) through PLC, automatically adjust the inlet valve to simulate the suction state, collect input voltage, current, input power, power factor, frequency, output power, and vacuum degree data from the test through PLC, and export the data through USB.

2. Based on the data from relevant tests, draw the relationship curves between vacuum degree, input power, speed, suction power, efficiency, and air volume

3. Equipped with a 17 inch monitor, it can display real-time detection of qualified/unqualified, test air volume, maximum/minimum air volume, speed, vacuum degree, input power, suction power, and efficiency; When the air duct is fully open/fully closed/partially blocked, test parameters such as maximum/minimum vacuum degree and input power and record them.

The tested data can be stored and test reports and curves can be output according to user requirements.

5. Equalizer box: According to the standard IEC60312 (Type A design)

6. Temperature compensation and modification: Correct according to the atmospheric pressure density specified in 5.2.8.4 of IEC60312

Online

Online Tel

Tel Contact

Contact Home

Home