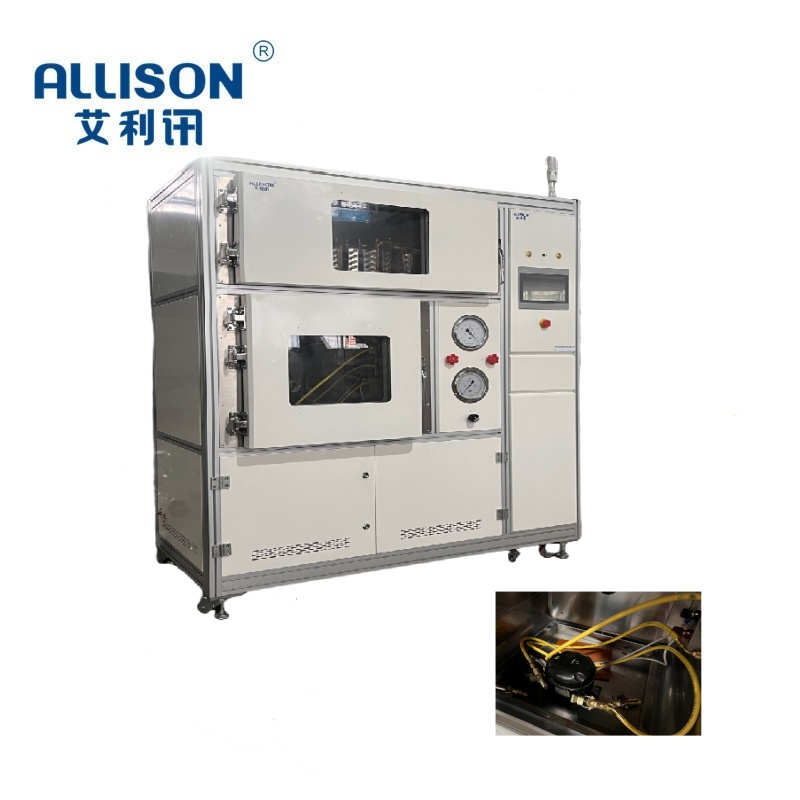

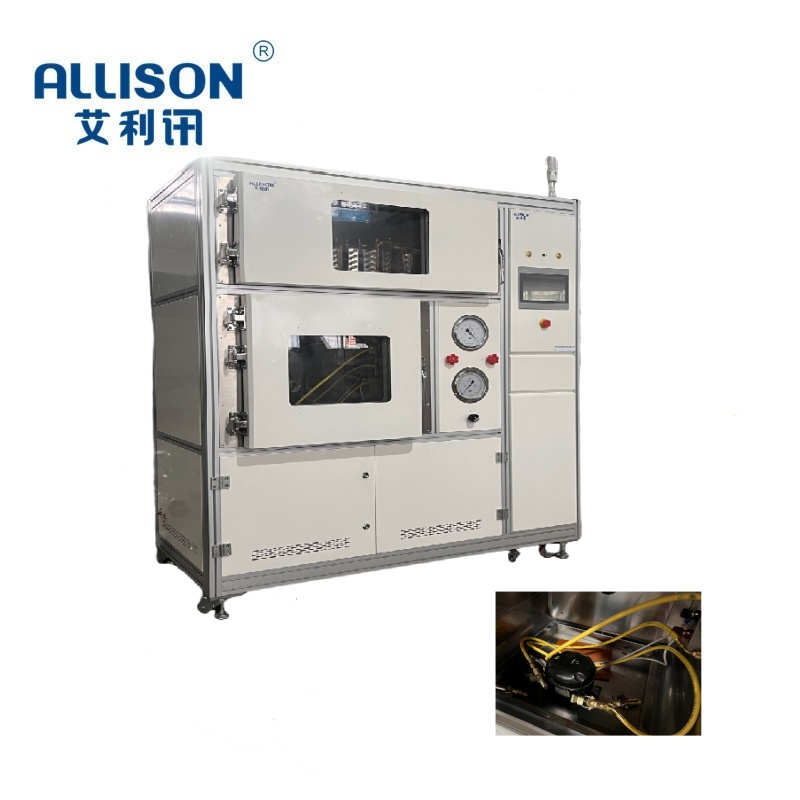

The comprehensive performance testing equipment for compressor environmental conditions is customized and developed according to relevant testing standards and industry standards. It uses simulated operating conditions to test multiple components such as compressors and condensers in a circuit. By simulating the actual operating conditions in the environment, the compressor is tested throughout the entire operation process. Conduct continuous voltage rise and fall test for compressor start-up, and conduct comprehensive performance testing on the tested compressor through the control system. And automatically record relevant test data.

3、 Main testing items of the equipment:

1. Liquid refrigerant method: used to test the condenser or evaporator side, calculating the heat transfer by measuring the flow rate of the liquid and the temperature difference between the inlet and outlet.

2. Input power/current test: The power and current values under specified operating conditions should comply with the regulations

3. Coefficient of Performance (COP): A key indicator for measuring the efficiency of a compressor, which is the ratio of refrigeration capacity to input power. The higher the COP value, the better the energy efficiency

4. Startup performance: Under specific voltage conditions (such as low voltage startup), the compressor should be able to start normally.

5. Durability (life test): It is usually required that the compressor can withstand a certain period of continuous reliable operation test.

Online

Online Tel

Tel Contact

Contact Home

Home