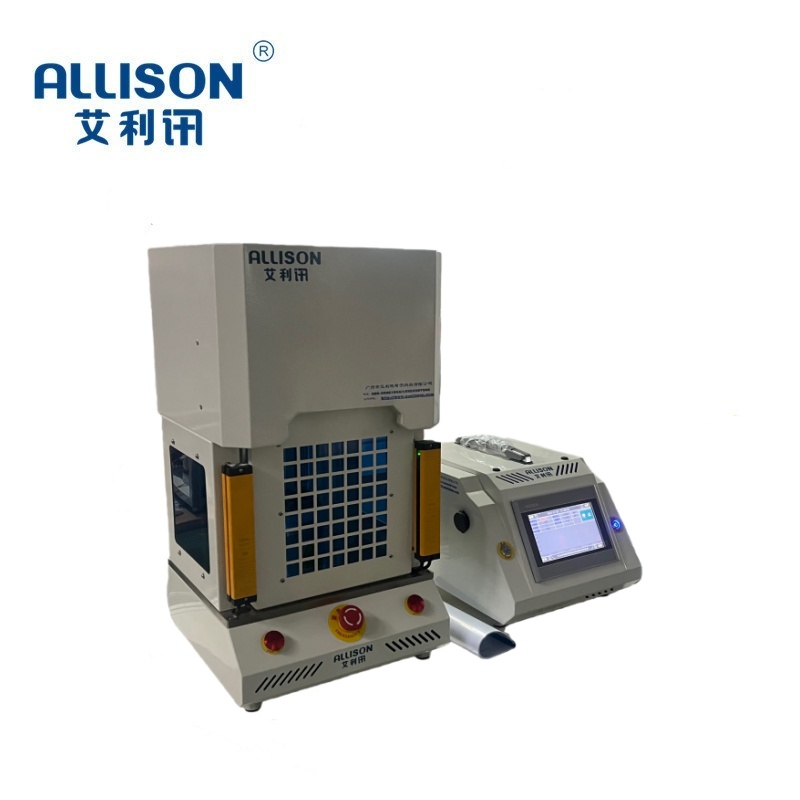

1. Explosion proof valve opening pressure testing equipment for battery cells, customized according to the relevant testing requirements and standards provided by customers, suitable for pressure opening testing of products such as caps and battery assemblies (battery specifications: cylindrical, 1865021700). The testing equipment adopts duplex alternating testing and is shared for pressure source output. Intervention and use of the testing station through valve body control. Two sets of high-precision pressure sensors are used for real-time pressure monitoring and data recording at two testing stations, and a pressure curve is generated to record the peak value (maximum pressure opening value). The testing data related to the opening pressure judgment (OK - qualified, NG - unqualified) is automatically recorded by the PLC.Explosion proof opening pressure test bench for battery cells

2. The testing platform adopts a built-in pressure boosting source to achieve low pressure source testing and high pressure source testing, and adjusts the pressure from 0.1-6.0Mpa through a high valve. The pressure regulation accuracy is 0.25 level, ensuring stable and controllable testing process. The dual station switching is automatically controlled by solenoid valves, which do not interfere with each other and improve testing efficiency. During the testing process, the system collects real-time pressure data and dynamically displays pressure curves and opening point values through a 10 inch touch screen interface. After the test is completed, the data is automatically saved and supports data traceability and statistical analysis.Explosion proof opening pressure test bench for battery cells

3. The equipment has multiple safety mechanisms such as overvoltage protection and leakage detection to ensure the safety of operators and the tested components. All pneumatic components are designed to withstand high pressure, with good sealing and long service life, meeting the requirements for long-term continuous operation.

4. The clamping part of the product adopts pneumatic automatic compression, and the silicone sealing diagram achieves effective sealing of both ends of the product. According to different test samples from customers, multiple specifications of samples can be tested by switching fixtures. It has the advantages of wide universality and quick fixture replacement. The testing area is equipped with a safety light barrier to prevent personnel from accidentally using it. Realize advantages such as high efficiency, safety, and convenient operation.Explosion proof opening pressure test bench for battery cells。

Battery core pressure test bench for anti-explosion opening; Airbag damper sealing inspection equipment; Vacuum negative pressure air tightness teste

Online

Online Tel

Tel Contact

Contact Home

Home