Automotive door handle durability life testing machine

Product Mode:

Fixed mode of products:

Test Speed:

Number of tests:

Equipment size:

Description:

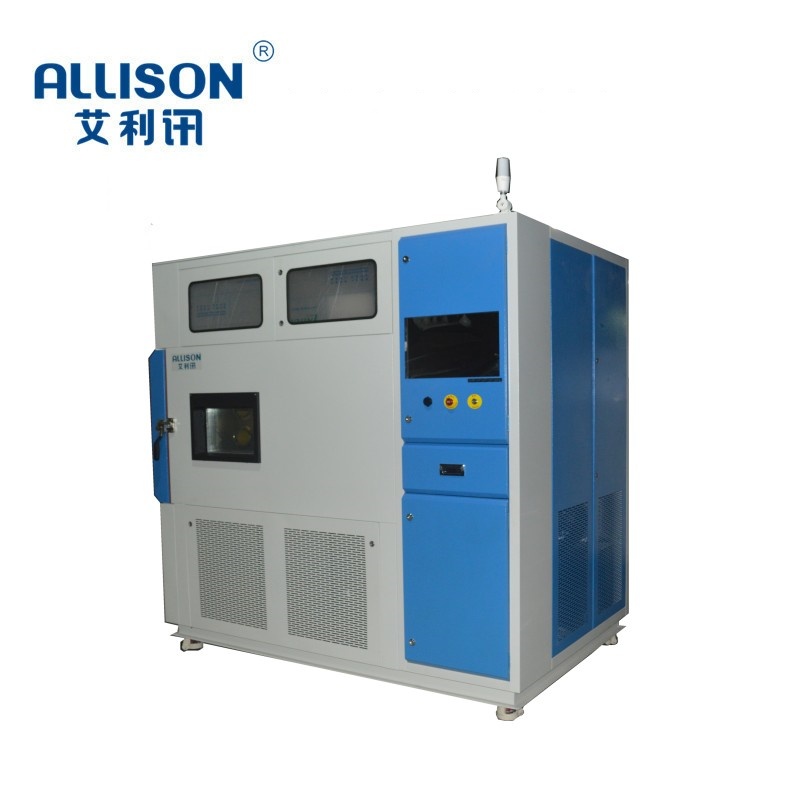

The door handle fatigue testing machine consists of an environmental simulation chamber and a life testing fixture The main body includes a high and low temperature environment test chamber, rack, base, test bench, electric servo, force sensor, and a self-developed PLC control system. During the product testing process, durability life testing is carried out in a certain environment. The door handle life is tested at different angles by adjusting the fixture position. Real time tension torque detection and life testing are performed on the tested door through data separation from servo motors and torque sensors. During testing, the system can achieve torque judgment based on relevant parameter settings, and automatically record the number and time of relevant non conformities. The device is designed according to the current mainstream, optimized for user-friendly design, with simple operation, easy understanding, and easy maintenance.

Online

Online Tel

Tel Contact

Contact Home

Home