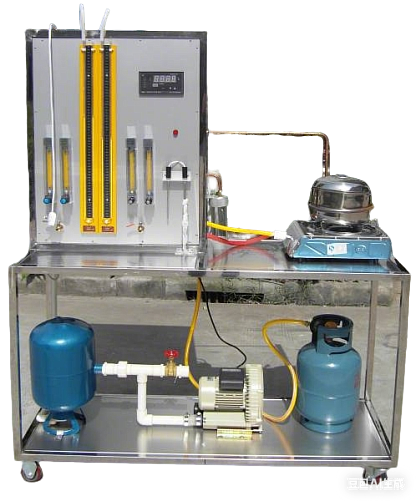

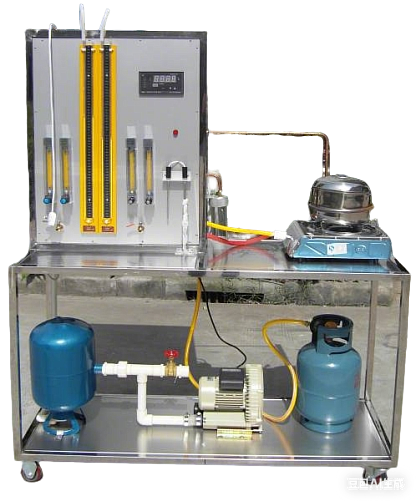

The test bench action structure is all pneumatic components, the punch cylinder and the rotary cylinder respectively achieve the pressure down the knob.ating ignition, the knob is released and the fire is burning, and then rotate to adjust the small fire burning, and the whole process of returning to the original position. The control uses PLC control. All digital display. It is suitable for all kinds of desktop stoves and built-in stoves for life test and performance comprehensive test, etc.

technical parameters:

1) The length and width of the mounting table can be adjusted, which can be easily installed on various different sizes and specifications of desktop stoves or builtin stoves.

2) The mechanical hand can be flexibly moved in three dimensions in any direction, and a knob, i.e., self-locking or inspection

3) There is a single stove, double stove selection function.

4) It has a flame detection function, using ion induction technology, if the ignition is not successful during test, the valve is automatically closed and the test is stopped and alarmed to prevent gas leakage.

5) The number of tests can be set from 0 to 99999 times, and the alarm is automatically prompted after the test is completed.

6) The number of successful ignition times can be counted. The number of consecutive ignition can be set arbitrarily, and there is an alarm function when the number of consecutive ignition failures reaches a certain time.

7) The time of each action of the valve body the experiment can be set, in seconds. For example: big fire time, small fire time, stop time, etc.

8) If there is a midway fire loss or flame during the test, there is an alarm and prompt function.

Online

Online Tel

Tel Contact

Contact Home

Home