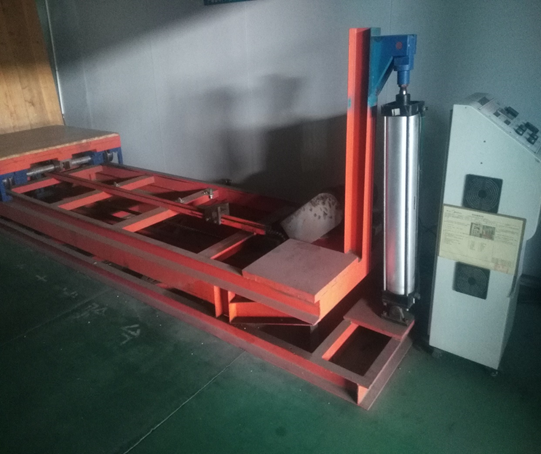

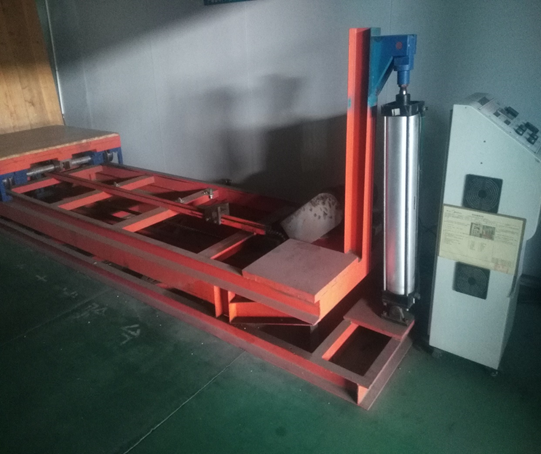

Overview:

The surface impact test equipment simulates the ability of product packaging to resist impact damage in the actual environment, such as handling, stacking of shelves, sliding of motors, loading and unloading of locomotives, transportation of products, etc. This machine can also be used as a scientific research institution, colleges and universities Colleges, packaging technology testing centers, packaging material manufacturers, foreign trade, transportation and other departments are commonly used test equipment for inclined impact. The machine complies with the international standard ISO2244-2001 (E) "Packaging-Part 5 of the complete and full transport package, horizontal impact test, inclined surface impact test, pendulum test" and the national standard GB/T4857.11—1992 "Packaging and Transportation" "Packaged Horizontal Impact Test Method" and other relevant technical indicators.

Related technical parameters:

1. Drive mode: electric + pneumatic

2. Sliding length: 2000mm

3. Weight of test piece: 200kg

4. Control system: PLC

5. Impact speed range: 1.305~2.608m/s (adjustable)

6. Impact speed error: ±5﹪

7. Trolley table size: 1000×1000 (MM)

8. Impact panel size: 1200×1800 (MM)

9. Outer ruler of testing machine: about 3500×1500×2100 (MM)

10. The surface material of the pulley table and the impact board is solid wood board

11. Working voltage: 220V 3.5KW

Online

Online Tel

Tel Contact

Contact Home

Home