Introduction:

1. IEC60335 home appliance temperature rise test angle and IEC60601 temperature rise test angle are designed and manufactured by Guangdong Safety Regulations in accordance with standard IEC60601-1 section 42.3, IEC60335-1 section 11.2, 11.3, and DSH591 CTL resolution requirements.

2. Standard requirements:

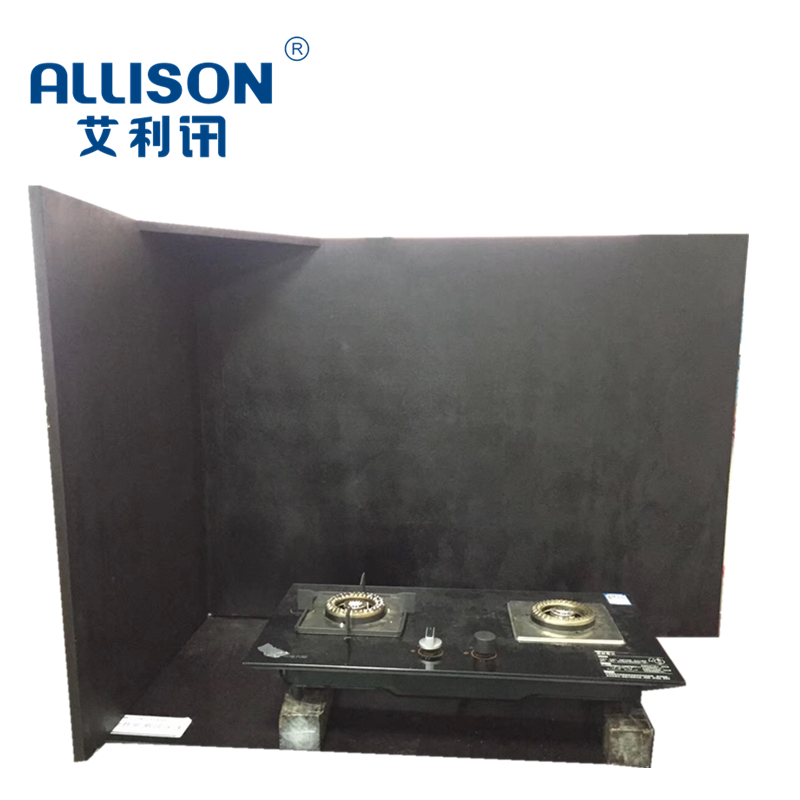

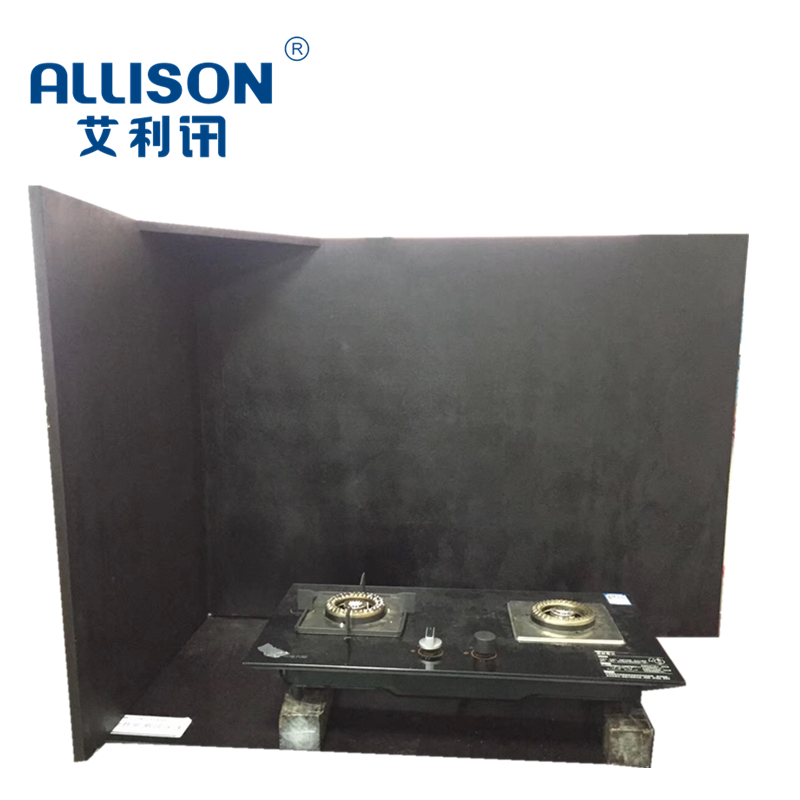

a. Utensils that are usually placed on the ground or on the desktop should be placed on the bottom plate and as close as possible to the two walls of the test corner.

b. For appliances that are usually fixed on one wall, refer to the instructions for use and fix them on one side wall of the test corner, and approach the other side wall as possible, and close to the bottom or top plate.

c. For appliances that are usually fixed on the ceiling, refer to the instructions for use and fix them on the top plate of the test corner, and approach the other side wall as possible, and close to the bottom or top plate.

d. Electric appliances that are usually placed on the ground or on the tabletop, placed on a horizontal support

e. Electric appliances usually fixed on the wall, fixed on a vertical support.

f. Electric appliances are usually fixed on the ceiling and fixed under a horizontal support.

g. Built-in appliances are installed in place according to the instructions for use.

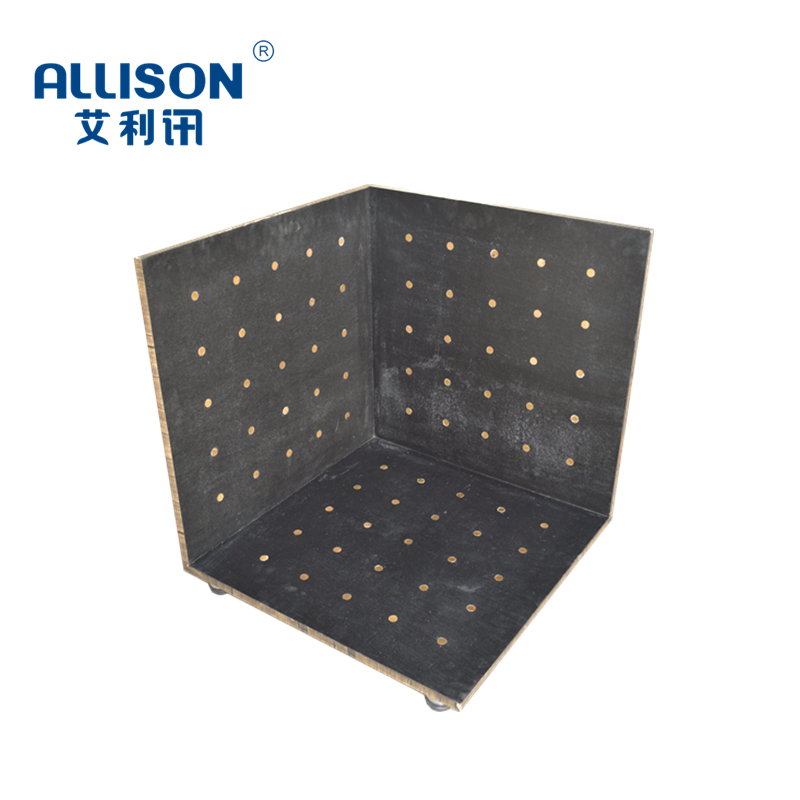

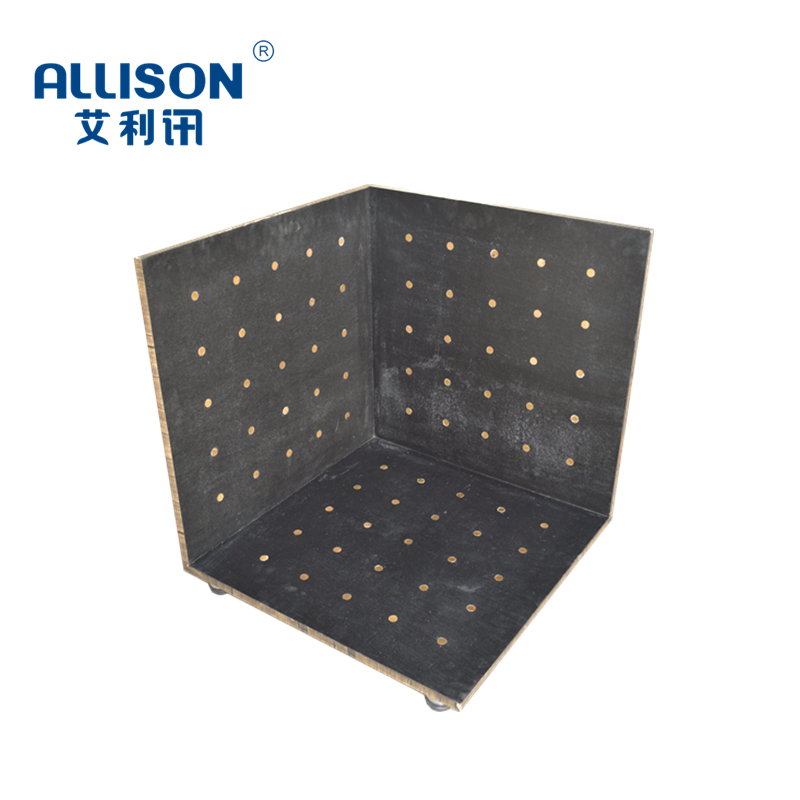

3. The installation facilities for test corners, supports and embedded appliances all use plywood with a thickness of about 20mm and coated with matt black paint.

4. The thermocouple used to determine the temperature rise of the test corner wall, top plate and bottom plate surface should be attached to the back of a small black disk made of copper or brass. The diameter of the small disk is 15mm and the thickness is 1mm. The front surface of the small disc should be flush with the surface of the plywood.

5. The temperature rise is determined by a fine wire thermocouple, which refers to a thermocouple with a wire diameter of not more than 0.3mm.

3. Technical parameters:

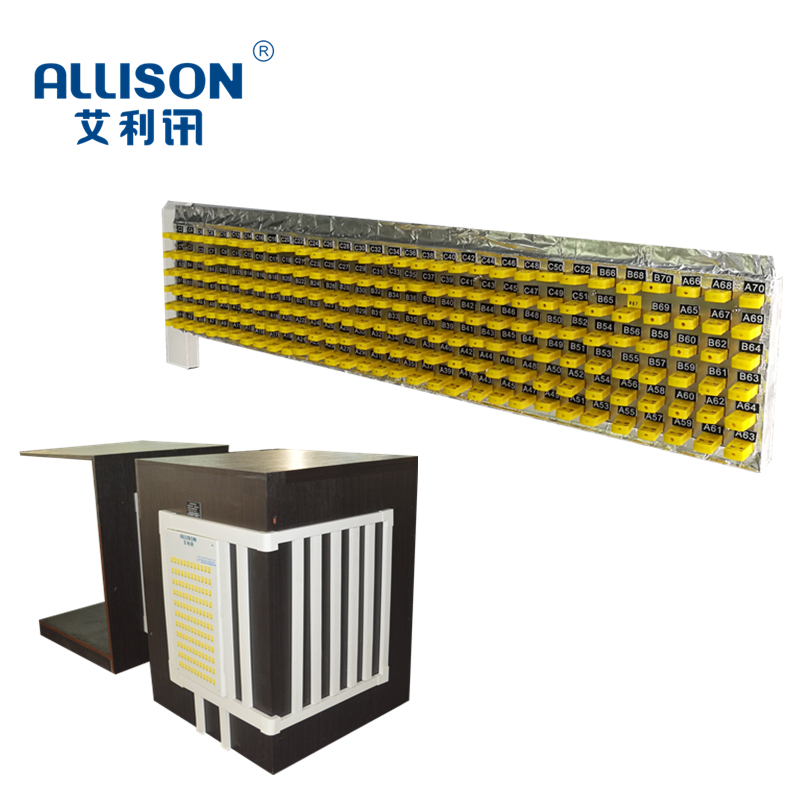

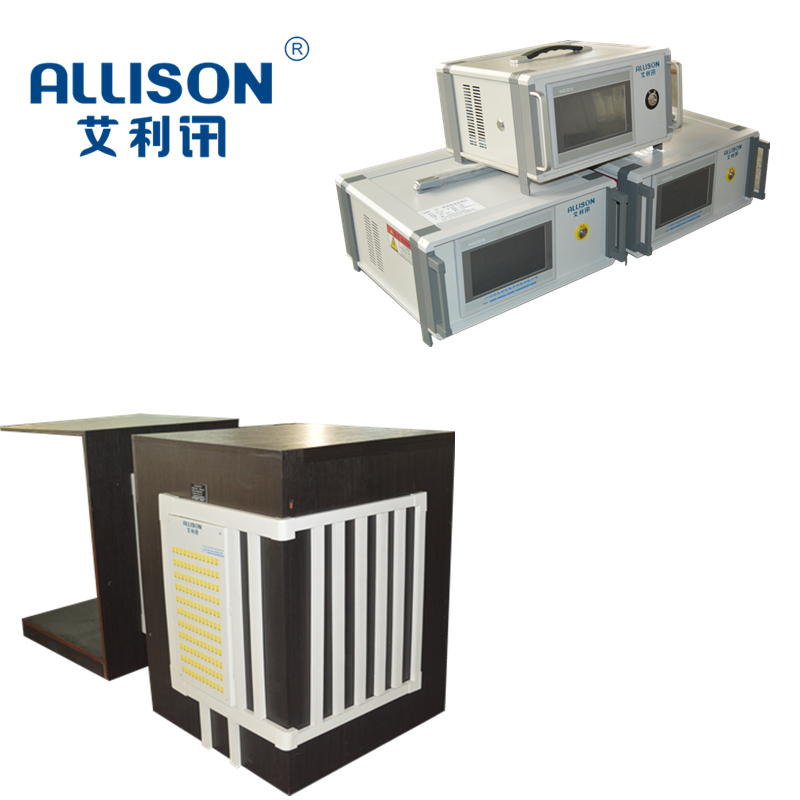

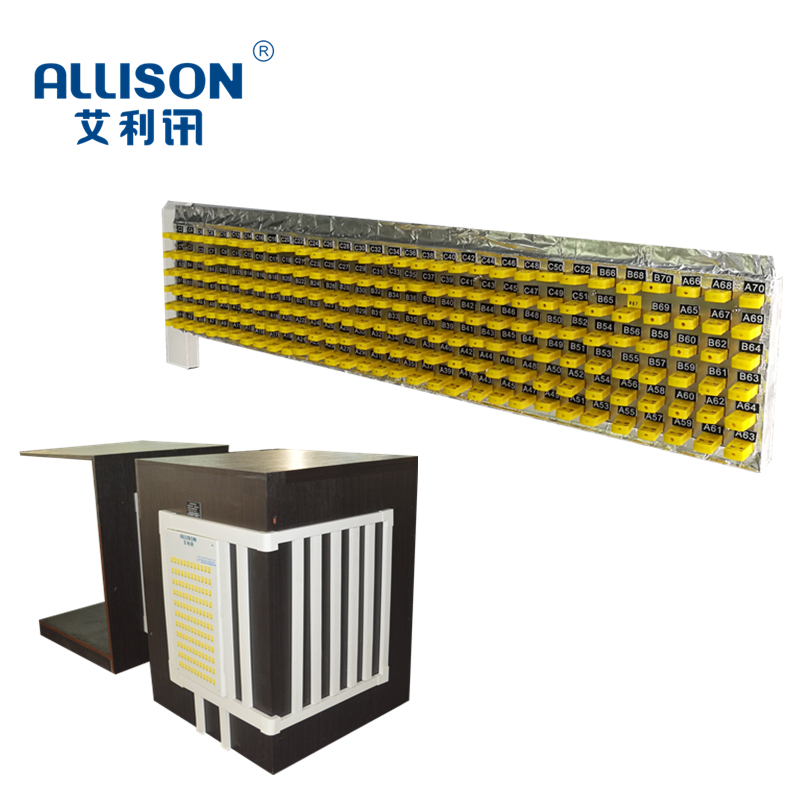

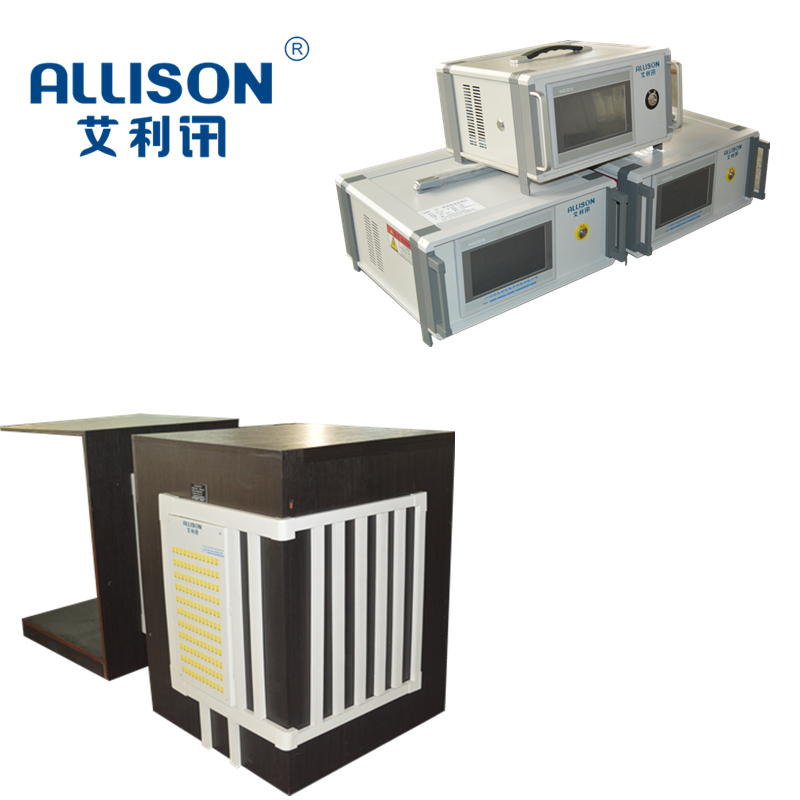

1. Size: It can be customized to be 1.2m long×2.0m wide×2.0m high, 1m long×1m wide×1m high, 0.8m×0.8m×0.8m or 0.6m×0.6m×0.6m, whatever you don’t need The size of splicing splint (the size of ordinary splint on the market is 1.22m×2.44m). A removable top plate or a fixed top plate can be added. The arrangement of top plate copper sheets and thermocouples needs to be confirmed in writing by the customer, otherwise 9-25 copper sheets are generally arranged by default. The specific arrangement of copper sheets is determined by specific agreement;

2. Thermocouple: Thermocouple with diameter less than 0.3mm, type K or J, thermocouple length 2 to 3 meters (optional), or use OMEGA original female terminal block, with male terminal and thermocouple, you can quickly connect On the temperature recorder, whether to configure a thermocouple, and what specifications to configure the thermocouple shall be determined in writing according to the customer's needs. The standard configuration does not include a thermocouple and thermocouple terminals;

3. Thermocouple layout: all lead out on one wiring block or optional thermocouple plug and socket (optional), whether the configuration needs to be negotiated by the customer, and the standard configuration does not include;

4. Temperature measuring copper sheet: 15mm diameter, 1mm thick brass sheet (optional), the quantity needs to be negotiated;

5. Number of temperature measurement points: 1 meter X 1 meter X 1 meter excluding the top 243 points, 0.8 meters × 0.8 meters × 0.8 meters excluding the top plate, a total of 147 points, 0.6 meters × 0.6 meters × 0.6 meters including the top plate, a total of 75 points, This item is optional, and the specific quantity needs to be determined in advance by the demander;

6. Arrangement of temperature measurement points: 100mmx100mm spacing, refer to CTL resolution;

7. Splint: the thickness of the splint is about 19-20mm, and the front is painted with matt black paint;

8. Movable part: 4 movable bottom wheels can be installed at the bottom to facilitate movement (optional).

Online

Online Tel

Tel Contact

Contact Home

Home