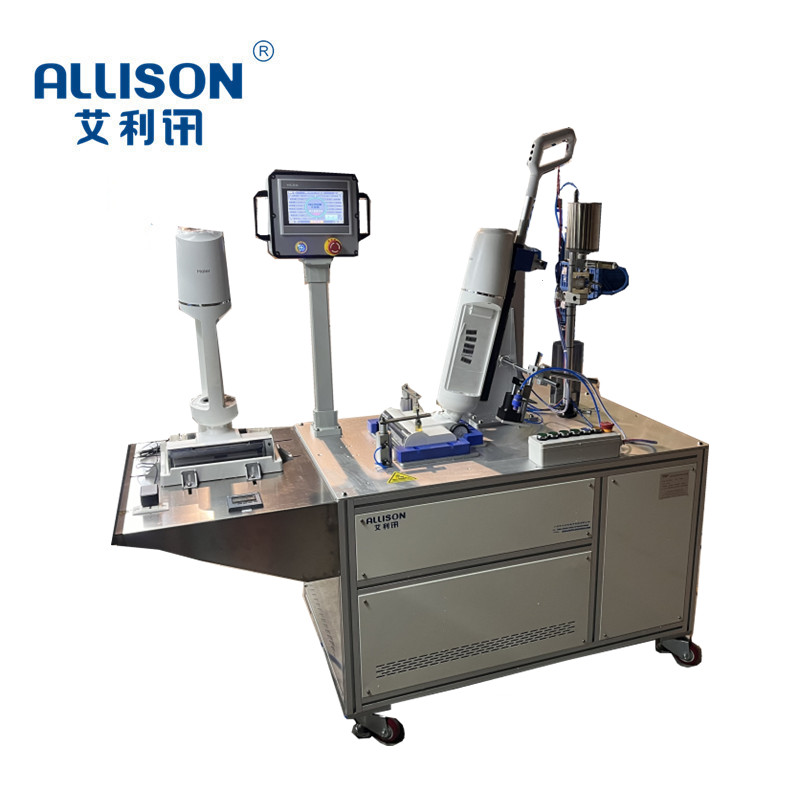

The function test-bed is designed according to the relevant industry standards and customer requirements. It is suitable for household cleaning appliances industry. The testing equipment is mainly used to test the whole machine testing function on the production line for the washing-suction integrated floor washing machine, and the switching of the testing mode is controlled by the program, the tested products were tested by the functions of sewage bucket full detection, sewage bucket on-site detection, vertical function test, electric box electrolytic water function test, rolling brush forward and reverse rotation detection, rolling brush blocking rotation detection, rolling brush rotation speed detection and so on. With the current production line rhythm production line, the product off-line before the whole machine function items for the full inspection process. By means of control program, automatic detection and data acquisition are carried out for the tested function test items of the whole washing machine. The system can collect positive and negative rotational speed signals and judge the related function test items with OK NG, the products tested by PLC automatically ok-qualified (green light display) , NG-- non-qualified judgment (red light display-and sound and light alarm) .

1.Test station: Unit Station

2. Size of test bench: W1150 × D680 XH 15500mm;

3. Control mode: PLC + 7-inch touch screen display

4, speed detection range: 0-5000 rpm

5, test time: 0-9999s can be set

6, production rhythm: about 30S/Table

7, judgment display: ok-qualified ng-unqualified

8, Data Test Data: USB Export

9, Device Power: 220V Power: 1.5 kw

Online

Online Tel

Tel Contact

Contact Home

Home