The utility model is suitable for monitoring the rolling brush module of the floor sweeper to realize the durability aging and temperature rise test

Of the power-on/power-off/forward/reverse rotation under different ground loads. PLC automatically adjusts the stroke height of the roller brush

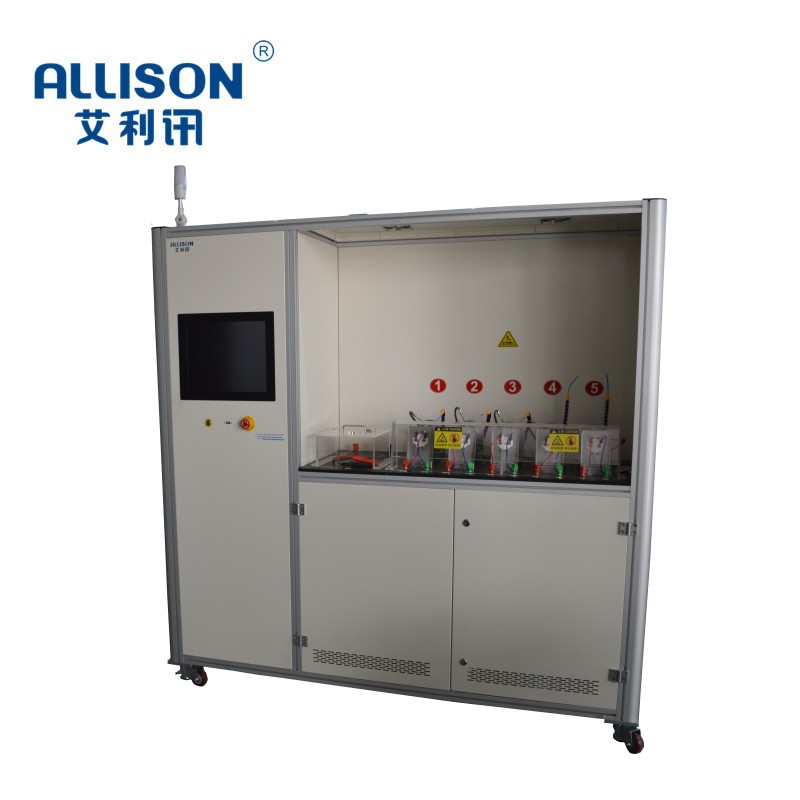

From the contact surface, thus increasing the friction degree between the roller brush and the contact surface. The testing machine is made of

40X40 aluminum profile structure and powder-sprayed sheet metal. Each station is equipped with working indicator.

The simulated loading aging test was carried out by switching different test ground. A key to start the use of simulated test conditions.

Users can also manually switch on and off, automatic switch on and off, height setting, voltage, current, speed, temperature

And other parameters

The test bench is arranged in 5 groups, 10 stations (left 5 + Right 5) . 0-60v adjustable voltage supply. Through PLC and 7-inch touch screen control. Relevant test times, test time, power-on time, interval on-off time and other cycle test settings. The related test data can be automatically recorded and exported with USB data

Main technical parameters:

1.Equipment Work Station: 6 Work Station left 3 right 3, altogether 5 groups

2.Touch Screen: 17-inch color touch screen, 1

3.PLC: Mitsubishi, Japan, memory function for data blackout

4.Input Voltage: 0-60 V adjustable

5.Other load mode: servo automatic downward pressure type

6.Test floor: wood floor, blanket, terrazzo floor

7.Interval: 0-999999 hours/min/sec

8.Time Range: 1-99999 hours/min/sec

9.Number of tests: 1-999,999

10.Height stroke adjustable range: 0-60 units: MM

11.Wiring: Fast Wiring Terminal

12.Safety Protection: emergency stop button

13.Equipment Power: 220V 50Hz about 2 kw

14.Equipment size: 1500X1050X1680 unit: MM

Online

Online Tel

Tel Contact

Contact Home

Home