1. Reference Implementation Standards: Enterprise Standards/customer requirements set. Through the black, white and gray of the calibration plate for

The program-controlled switch, through the PLC to reflect back the laser data sampling and the actual value comparison. The data are automatically

uNmbered and Excel , and the standard deviation and the comparison with the set accuracy standard are automatically calculated by software.

The testing machine has the advantages of strong versatility, stable operation, simple operation, convenient control and low failure rate

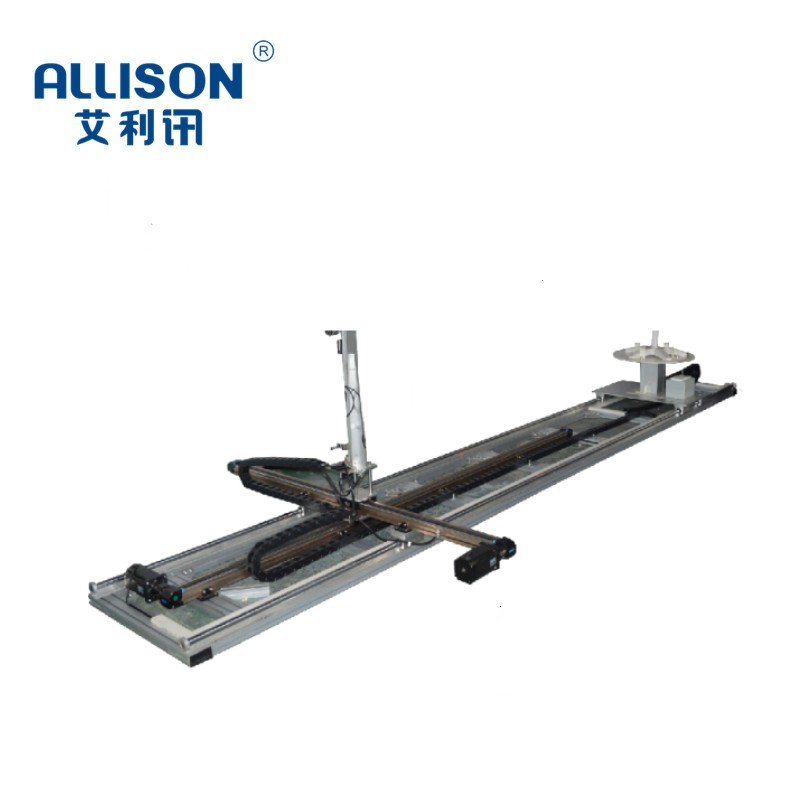

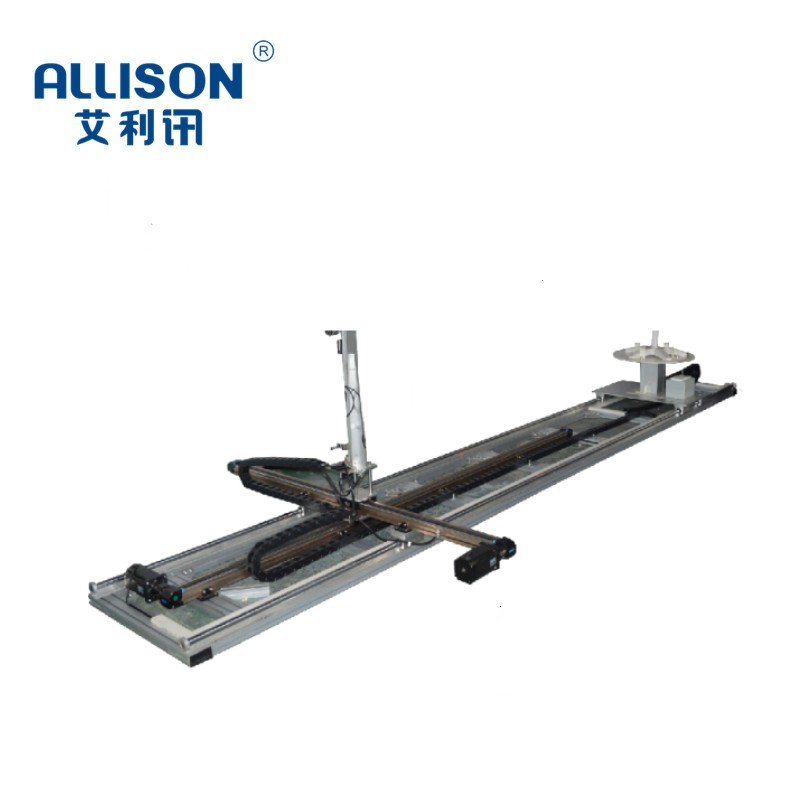

2.The equipment mainly consists of test bench, moving track, triangle calibration plate, fixture fixed plate, control system and so on.

The whole main frame of LDS ranging precision test-bed is made of 4080 euro standard profile, the dimension is about

10400mm * 800mm * 800mm * 800mm. The reflected laser signal is sampled by PLC and compared with the actual value, 0-100 data

Are collected for data comparison by test program. After data sampling, the system automatically generates serial numbers and Excel

Reports. Data export is carried out via USB, the standard deviation is calculated by the program and compared with the standard of setting

precision, and is judged automatically

Main technical parameters :

1.Test station: Single Station

2.The size of the test-bed is W1080 × D800 × h 1250mm

3.Control mode: PLC 17-inch touch screen display

4.Calibration Board switching mode: servo control 0-360 ° range of programming, accuracy 1 °

5.Wiring: the use of fast clamp seat

6.Track: Servo Module 0-1.5 m/s settable

7.Supply voltage range: 0-36V adjustable

8.Calibration board color: black, white, Gray

9.Travel Range: 0-10000mm accuracy 1mm

10.Judgment: Upper and lower limits set judgment

11.Power supply: 220V 1.5 kw

Online

Online Tel

Tel Contact

Contact Home

Home