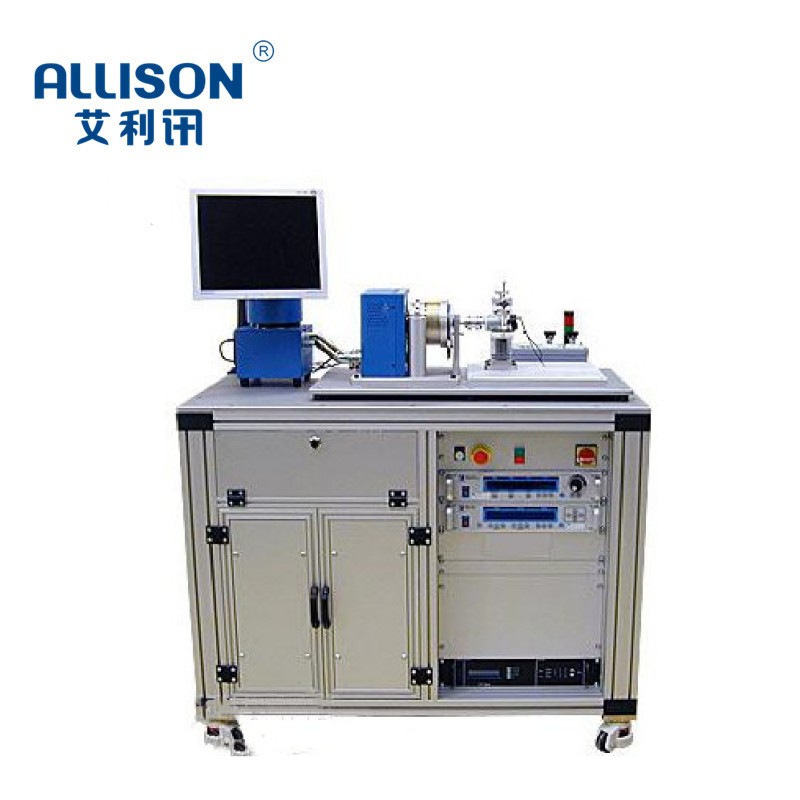

Motor testing equipment is based on the customer to provide relevant technical parameters customized. Through independent research and development, the test system uses the brake as the loader, the torque and speed sensor for the motor torque test, the electric quantity transmitter for the motor electrical parameters test, to complete the voltage measurement, current measurement, speed measurement, power measurement, efficiency measurement, Hall phase signal acquisition and detection functions, noise acquisition and testing

Main technical parameters:

1.Test channel: single path detection

2.Touch Screen: 17-inch color touch screen

3.PLC: Mitsubishi, Japan, the data power failure memory function, the setting window to be able to set the password lock

4.Input Voltage: AC: 0-250V adjustable DC: 0-36V adjustable, detection accuracy: 0.5 level

5.Current detection range: 0-30A detection accuracy: 0.5 level

6.Clamping mode: quick clamping

7.Detection Scope: No-load test, load test, blocking rotation test, motor efficiency test, durability test, T-N curve test, back EMF test, driving performance test, temperature rise test

8.Test times, period: 1-99999999 times

9.Temperature acquisition: 4-channel K-type

10.Torque Detection Range: 0-30n. M (according to customer requirements)

11.Wiring: Fast Wiring Terminal

12.Power Supply: 3-wire system

13.Equipment size: 1950X700X1650 unit MM

14.Instrument power supply: 220V 50Hz 3.5 kw something

Online

Online Tel

Tel Contact

Contact Home

Home