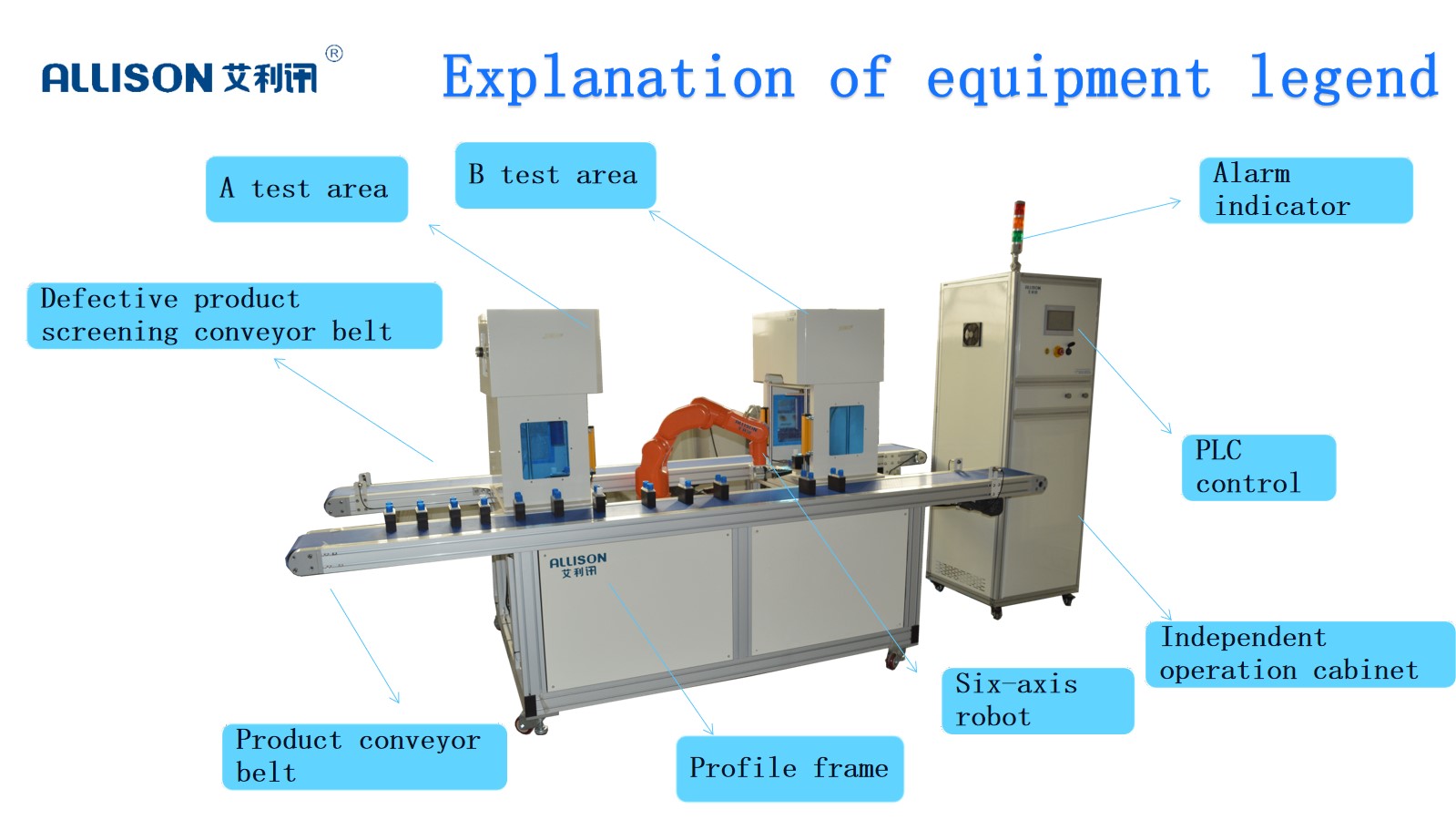

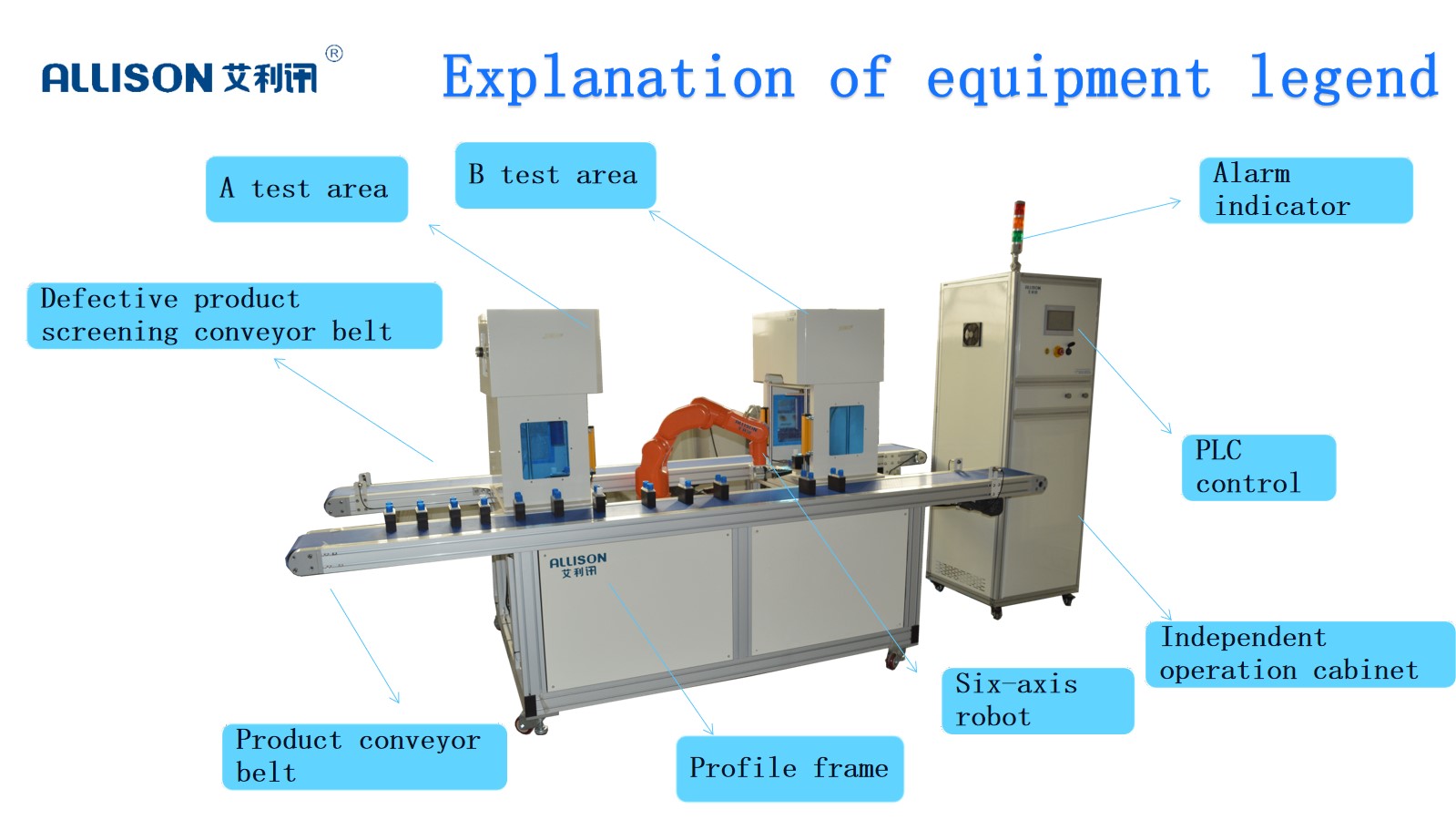

Fully automatic sealing testing equipment, composed of self-developed high-precision double differential pressure sensors. The six-axis manipulator cooperates to replace the traditional manual process of picking and placing test samples. Effectively improve the efficiency and accuracy of product offline. The test equipment has functions such as foolproof, automatic screening of qualified and unqualified, automatic judgment of leakage value, identification, and visual inspection of appearance. Realize 24 hours continuous work. The system is easy to operate, and the accessories used are imported and domestic well-known brands, and the work is stable and reliable.

The test equipment is generally used for multi-mode testing of high pressure, low pressure, and negative pressure leak detection. Non-standard customization can be made according to customer samples and related requirements.

technical parameter:

1. Number of stations: single station (1-8 stations are optional)

2. Pressure detection mode: high pressure test mode, low pressure test mode, negative pressure test mode, high and low pressure negative pressure continuous test mode.

3. Control method: PLC Japan Mitsubishi

4. High pressure test pressure: 10~1200Kpa arbitrary adjustment

5. Low pressure test pressure: 10~600Kpa arbitrary adjustment

6. Negative pressure test pressure: 0-negative 100Kpa

7. Test pressure level: 0.1 level

9. Use single-phase power supply with ground wire: AC220V±10%, 50Hz 0.75KW

10. Equipment size 2500 X 1250 X 1280 Unit: MM (with this according to sample equipment

Online

Online Tel

Tel Contact

Contact Home

Home