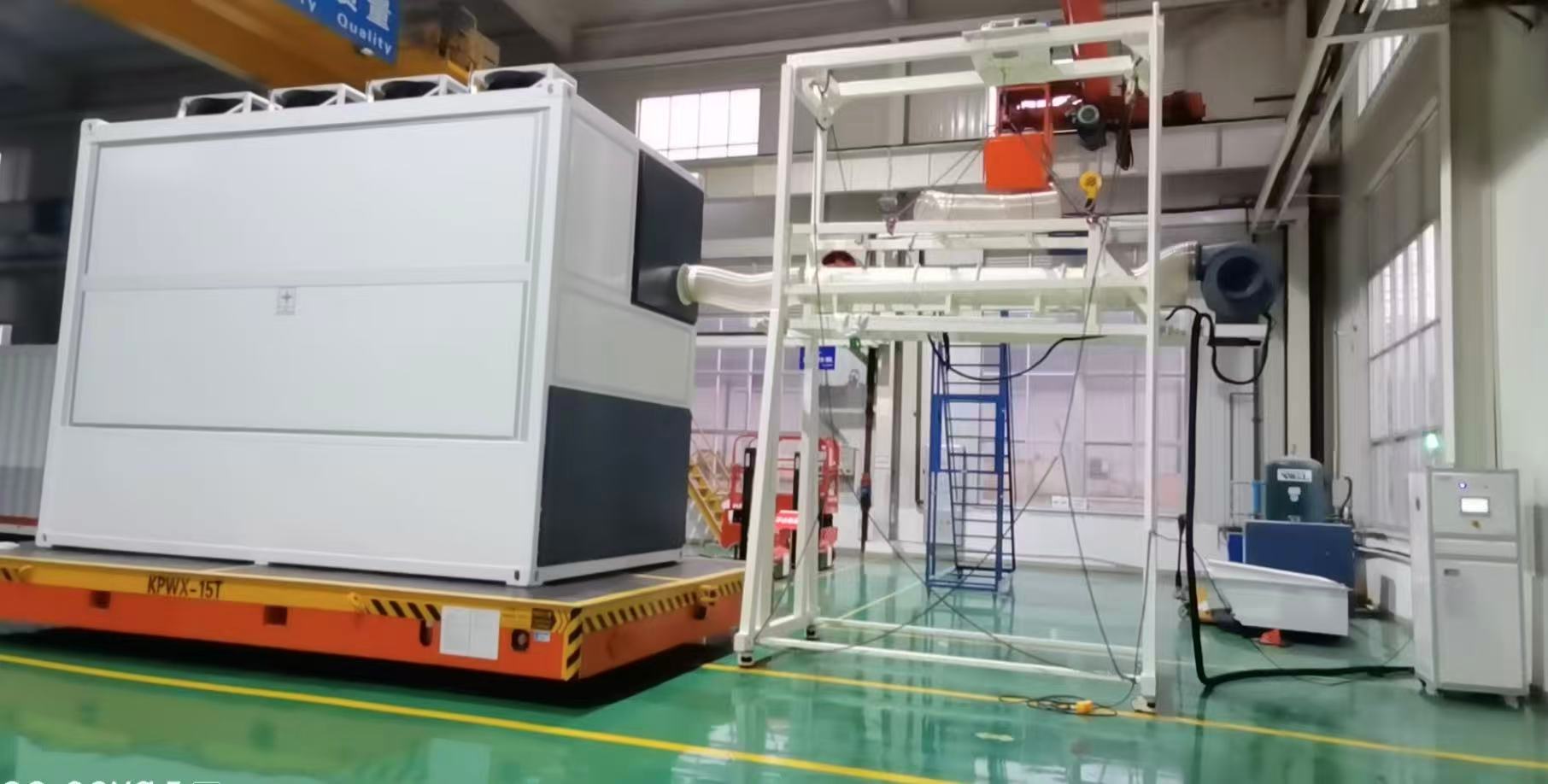

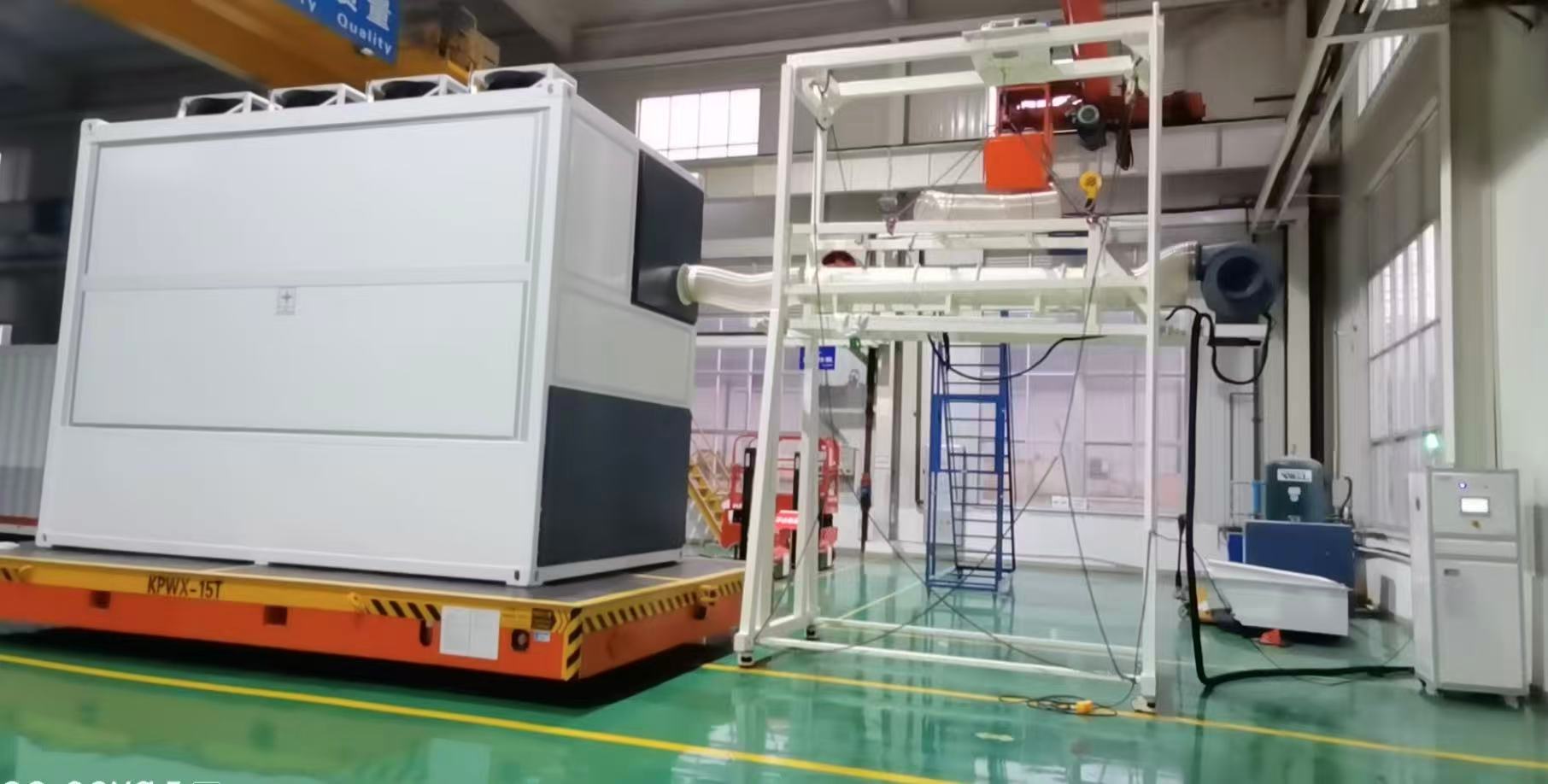

This testing system is specifically designed for testing the performance of radiators. The entire control testing system adopts automatic control mode,

Meet the needs of performance testing for various types of radiators and fans.

The system adopts EtherNet communication method, which is convenient, flexible, and has high anti-interference performance. The software system is based on the user's actual usage habits

We have developed a more thoughtful and practical testing system based on our habits and special requirements.

The automatic control and measurement method of this testing system adopts a computer centralized distributed measurement and control system design, consisting of a data system

The lower level control computer collects and displays data, while the upper level main control computer analyzes and processes the data collected by the lower level control computer

Manage and issue set value instructions and data acquisition instructions to the lower level control machine to complete the entire system's work.

The measurement principle of this testing system is the obstruction type flow measurement principle, using a standard long diameter low-speed nozzle as the obstruction, and measuring through

Measure the air flow through the nozzle by measuring the static pressure difference at both ends of the standard nozzle.

The measurement range of this testing system is 2.5-250 CFM. Static pressure range: 0-200mm Aq.

Set static pressure (external residual pressure) control:

Select the nozzle according to the specimen specifications, input the static pressure value of 0 (or external residual pressure value) into the computer, and the system will automatically run and calculate the air flow

Quantity; Changing the residual pressure value system will result in a new air volume value, which can be measured to obtain the air volume wind pressure curve.

Nozzle selection: The system will automatically determine whether the nozzle selection is appropriate during the experiment and provide a prompt.

Control instruments:

Model: Yokogawa UT series; Input: 4-20mA DC; Output: 4-20mA DC;

Control accuracy: ± 0.15%;

Automatic measurement of air volume and pressure:

Measurement parameters: air temperature (T), air humidity (φ), atmospheric pressure (B), and static pressure difference before and after the nozzle (Δ P).

Data acquisition module

Model: ADAM6000; Input: 4-20mA DC; Output: EtherNet

Accuracy: ± 0.15%;

Online

Online Tel

Tel Contact

Contact Home

Home