Sensor concentration analysis testing system IEC 60335-2-40:2022 testing equipment

Flammable refrigerant monitoring system standard IEC TS 63542_2024

IEC TS 63542:2024

The International Electrotechnical Commission (IEC) released the first version of the standard IEC TS 63542:2024 for combustible refrigerant monitoring systems on August 13, 2024. IEC TS 63542:2024 is applicable to refrigerant detection systems that comply with the IEC 60335 series of relevant standards in appliances using combustible refrigerants.

The relevant standards of the IEC 60335 series include:

·IEC 60335-2-40: Special requirements for heat pumps, air conditioners, and dehumidifiers

·IEC 60335-2-89: Special requirements for commercial refrigeration equipment and ice makers with integrated or remote refrigerant units or motor compressors

·IEC 60335-2-104: Special requirements for appliances for recovering and/or recycling refrigerants from air conditioning and refrigeration equipment

·IEC 60335-2-118: Special requirements for professional ice cream machines

The testing system is mainly aimed at addressing global climate change and peak carbon neutrality. Countries and regions such as Europe, the United States, and Australia have introduced relevant regulations and policies prohibiting high global warming potential (GWP) refrigerants. Starting to develop and produce low GWP combustible refrigerant products represented by R32, R290, R600a, and R1234yf for enterprises. However, the use of these flammable refrigerants increases the risk of product flammability and explosiveness. For safety reasons, when the charging amount of combustible refrigerant in air conditioning exceeds a certain range, IEC 60335-2-40: Annex LL takes the lead in providing testing requirements for combustible refrigerant monitoring systems.

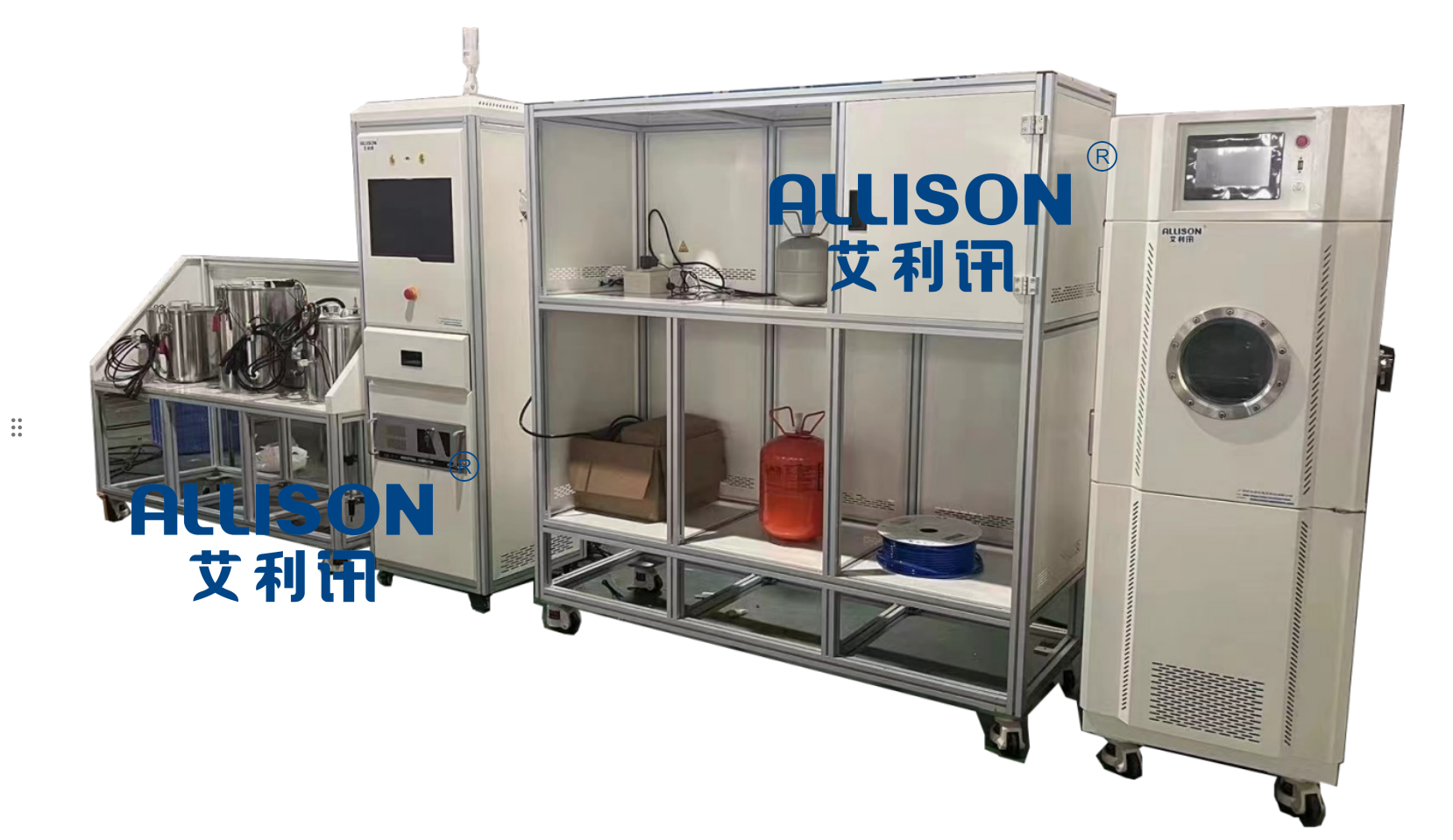

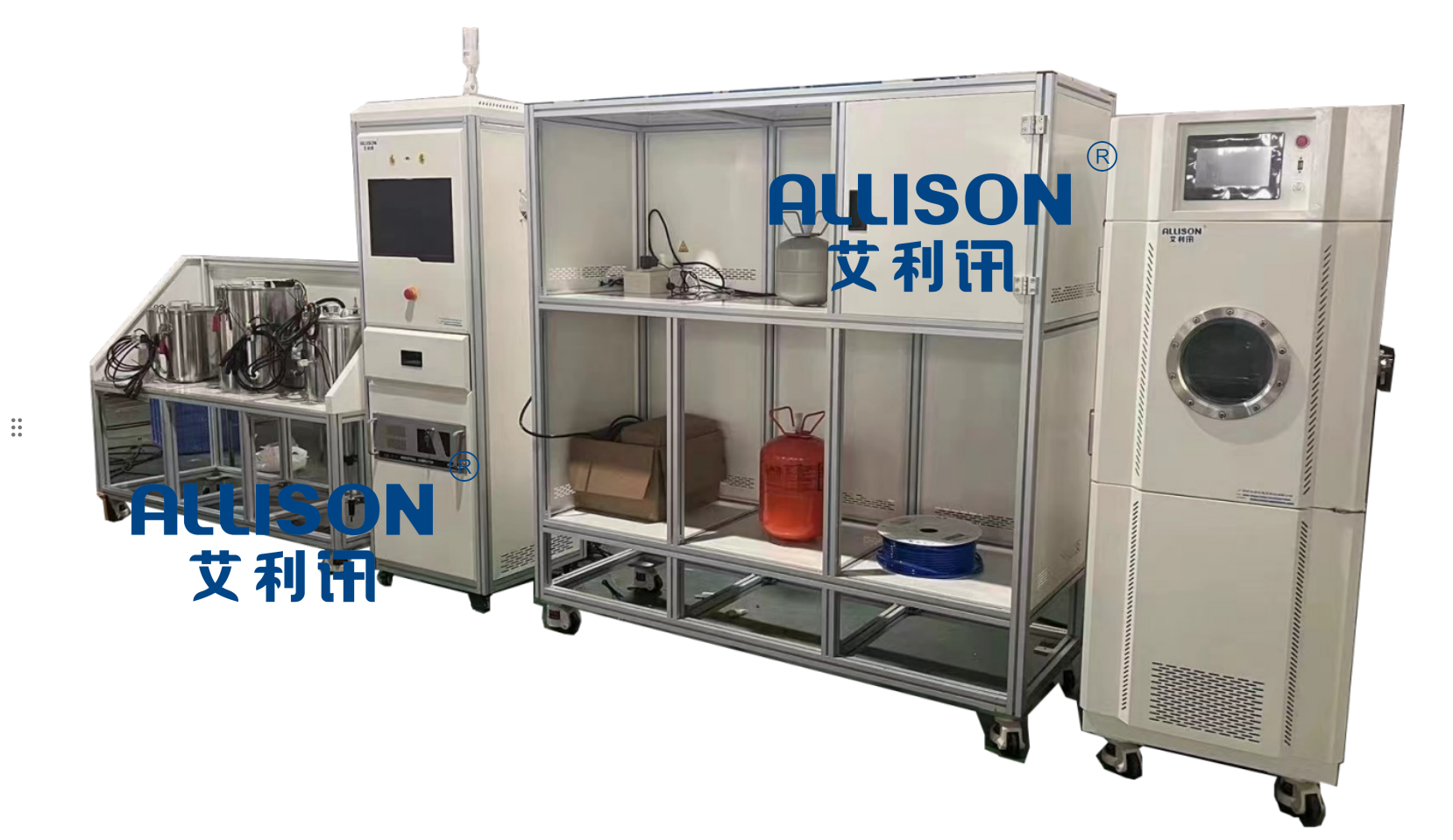

Equipment Introduction:

1.The testing equipment for combustible refrigerant detection system is mainly developed and customized according to the relevant testing standards IEC 60335-2-40 and the technical parameters provided by customers. Mainly applicable for the analysis of different refrigerant gas concentrations and the analysis and testing of sensor concentration signals. By using different refrigerants for concentration simulation testing, quantitative injection is carried out into the tested chamber, and the gas concentration inside the explosion-proof testing chamber is controlled by a program and a gas concentration generator to provide a simulated environment for gas concentration generation and testing. And monitor through a concentration analyzer, collect and analyze data from the tested sensors through PLC. Compare and analyze computer data through PLC, concentration analyzer, and information acquisition section. And the data is automatically recorded and saved by the control computer. The concentration analysis testing system is suitable for fields such as research and development, manufacturing, and quality management. The testing equipment has a simple and intuitive system for use. The test results are automatically stored and can be exported through USB and other functions.

2.The analysis and testing system mainly consists of high and low temperature explosion-proof environment testing chamber, concentration analysis system, refrigerant release regulation device, response testing device, toxicity testing device, oil mist testing device, explosion-proof testing device, central control system, etc.

3.High and low temperature explosion-proof environment testing chamber: adopting an explosion-proof structure, the internal space volume is not less than 50L, and the working size of the internal space is about 350mmX350mmX500mm. The testing chamber tests the sheet metal and profile frame structure, with an inner box made of non steel and an outer powder coating, resulting in a simple and beautiful appearance. The top is equipped with an explosion-proof door, which can effectively prevent the occurrence of box explosion during the testing process, greatly improving the safety of the experimental process. The internal configuration includes a ventilation system and opposite exhaust function, effectively preventing refrigerant leakage during testing. Compressed air is used for rapid ventilation, greatly improving the purification of the testing chamber and the leakage of harmful gases.

4.The concentration analysis system detection system uses a gas concentration analyzer to detect the concentration of different types of refrigerants. The refrigerant detection system can switch modes and is suitable for response testing, toxicity testing, oil mist testing, and monitoring in high and low temperature environments. Real time detection and analysis of refrigerant concentration through signal acquisition. When the refrigerant concentration reaches or exceeds the alarm setting, the data acquisition system has the function of automatically reading relevant data and providing alarm prompts. Compare the data of the analyzer and sensor through PLC to make data judgments. The relevant test data and test results are automatically stored by the system and can be exported through USB.

Online

Online Tel

Tel Contact

Contact Home

Home