System Architecture Composition

This system is a modular integrated test platform, mainly consisting of the following major units:

2.1 Environmental Control and Test Chamber Unit

Function: Provide a stable test environment that meets standard requirements, ensuring the reproducibility and comparability of test.

Structure Composition:

Insulated Test Chamber: The internal effective dimensions shall not be less than (L) 3.0m × (W) 2.m × (H) 2.2m. The inner walls are made of smooth, easy-to-clean, low-adsorption material.

Constant Temperature and Humidity: A precise air conditioning unit ensures that the environmental temperature inside the chamber is controlled at 23±2°C and the relative humidity is controlled at 50±10% (complies with IEC 62885-1 Clause 5.2).

Air Purification and Circulation System: High-efficiency partic air (HEPA) filters and low-speed circulating fans ensure that the test background dust concentration does not affect the weighing accuracy.

Lighting System: Uniform shadowless lighting the needs of operation and observation.

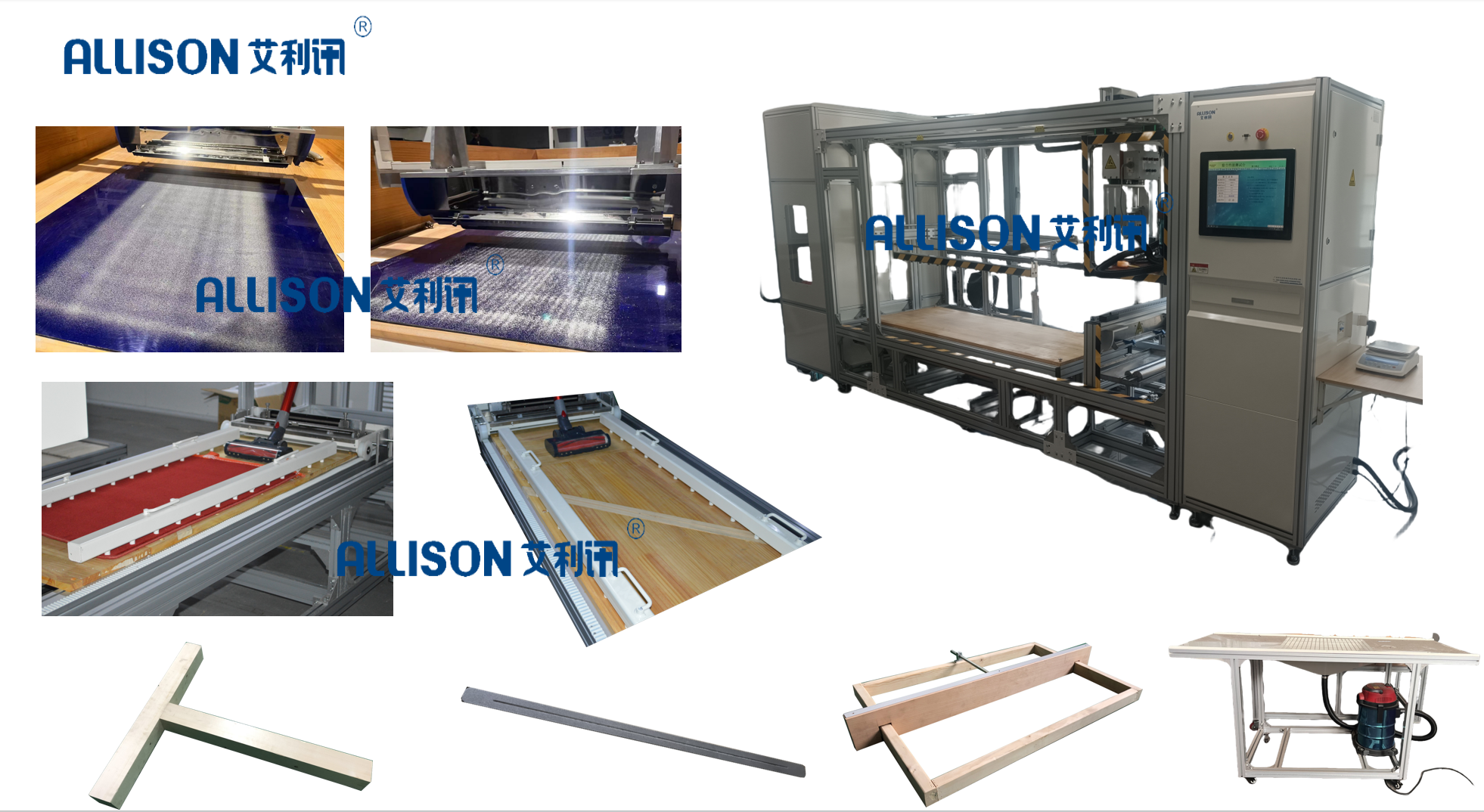

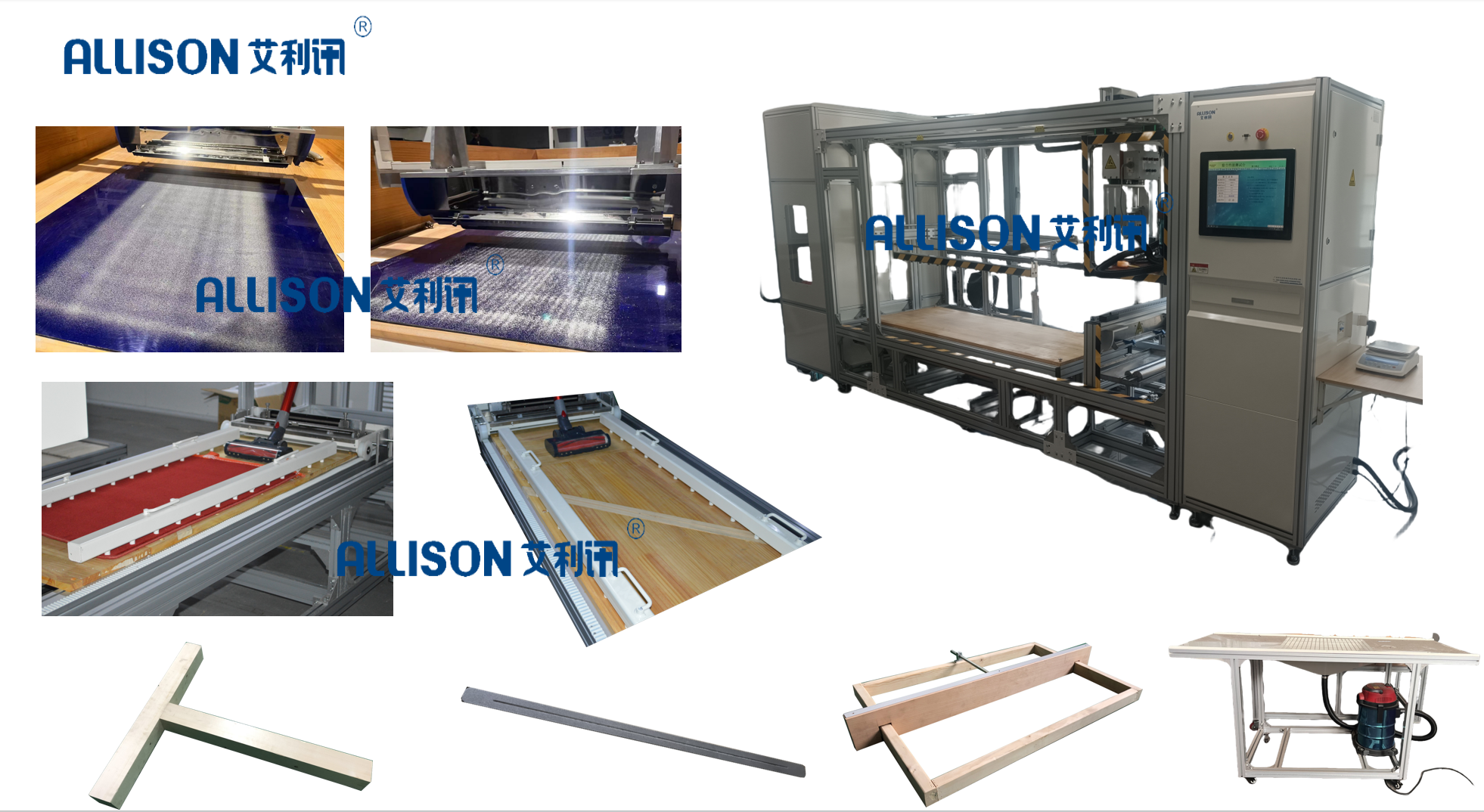

2.2 Standard Test Base Plate and Motion Control Unit

Function: Carries the standard test floor and drives the vacuum cleaner to automate at a specified path and speed.

Structure Composition:

Standard Test Floor Components:

Fluffy Test Carpet: Complies with the requirements of Appendix B.1 of standard, with a unit area mass of 750±50 g/m², and a size of ≥ 1.0m x 1.5.

Cut Pile Test Carpet: Complies with the requirements of Appendix B.2 of the standard, with a pile height of 5±0.5 mm, a size of ≥ 1.0m x 1.5m.

Hard Test Floor: A smooth, non-porous, non-conductive laminate similar material with a size of ≥ 1.0m x 1.5m.

Automatic Walking Mechanism:

Linear Module: High-precision ball screw orous belt module, with X/Y axes arranged vertically.

Vacuum Cleaner Mounting Platform/Fixture: Can firmly install the tested vacuum cleaner host and nozzle and the platform has a height fine-tuning function to ensure that the contact pressure between the nozzle and the test surface meets the standard.

Motion Controller: Programmable Logic (PLC) or industrial computer, with built-in standard test programs (such as "W" shape or straight reciprocating path).

Drive Motor: Servo or stepper motor, with speed control accuracy of ±1%, ensuring the cleaning speed is 0.5 ± 0.05 m/s (complies with Article7.4.3 of the standard).

Standard Test Dust and Distribution Unit

Function: Accurately distribute standard test dust in a repeatable and uniform manner within the test area.

Structure Composition:

Standard Test Dust: Complies with "Test Dust A" specified in Appendix A of IEC 62885-1alternative to the Arizona Test Dust), including specific components and particle size distribution such as quartz sand, black smoke ash, and textile cotton lint. A valid component and size analysis report must be provided.

Automatic Dust Distribution Device:

Dust Feeder: A precise quantitative feeding device with a dust feeding accuracy of ±0.01.

Distribution Mechanism: Using vibration sieving, rotating brush, or compressed air diffusion technology, it ensures that the dust is evenly distributed within the test area (such as rectangular area of 1.0m x 0.2m) (Article 7.4.2 of the standard).

Control System: Controls the amount of, the area of distribution, and the time of distribution.

2.4 Precision Weighing and Data Acquisition Unit

Function: Accurately measure key mass parameters, is a direct basis for calculating the cleaning rate.

Structure Composition:

High-precision Analytical Balance: Range: ≥ 2000g Readability:0.001g

Wind Shield: Essential to eliminate the influence of airflow on weighing.

Dust Bag/Dust Box Weighing Tray:ized special tray for weighing

Online

Online Tel

Tel Contact

Contact Home

Home